The demand for CNC aluminum parts is growing rapidly in various industries. These components offer strength, durability, and precision. Whether you are in aerospace, automotive, or electronics, CNC aluminum parts play a crucial role in enhancing project outcomes.

Understanding the best options available is essential. High-quality CNC aluminum parts can significantly improve the performance of your projects. However, not all parts are created equal. It's important to choose components that meet both your specifications and quality standards.

While there are many choices, mistakes can happen. Some may overlook the importance of sourcing from reputable suppliers. Others may focus solely on price, neglecting to consider the long-term benefits of investing in quality. In this article, we will explore the top CNC aluminum parts for 2026. Refining your selections can lead to remarkable improvements in your projects.

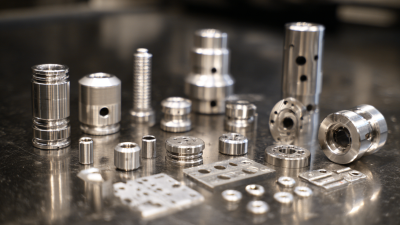

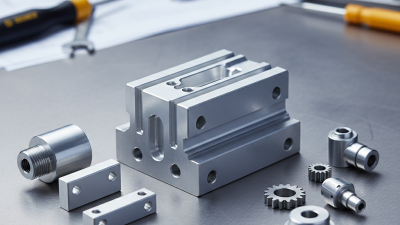

CNC machining has revolutionized the way aluminum parts are produced. By employing computer-controlled tools, manufacturers can achieve high precision and repeatability. This technology allows for intricate designs that would be challenging or impossible to create manually. For instance, complex shapes and tight tolerances are easily manageable, making CNC machining a preferred choice for many industries.

The importance of CNC machining in aluminum parts cannot be overstated. It ensures consistent quality throughout the production process. However, it’s essential to acknowledge the challenges it presents. For example, the initial setup can be time-consuming and costly. Mistakes in programming or tool selection can lead to material wastage. Despite these risks, the benefits often outweigh the downsides. Ultimately, effective CNC machining can enhance product functionality and performance.

Incorporating CNC technology into your projects can significantly improve outcomes. Designers must constantly adapt to evolving techniques. Staying informed about advancements is crucial. This way, you can leverage the full potential of CNC machining for your specific aluminum part needs. Embracing this technology demands continuous learning and reflection.

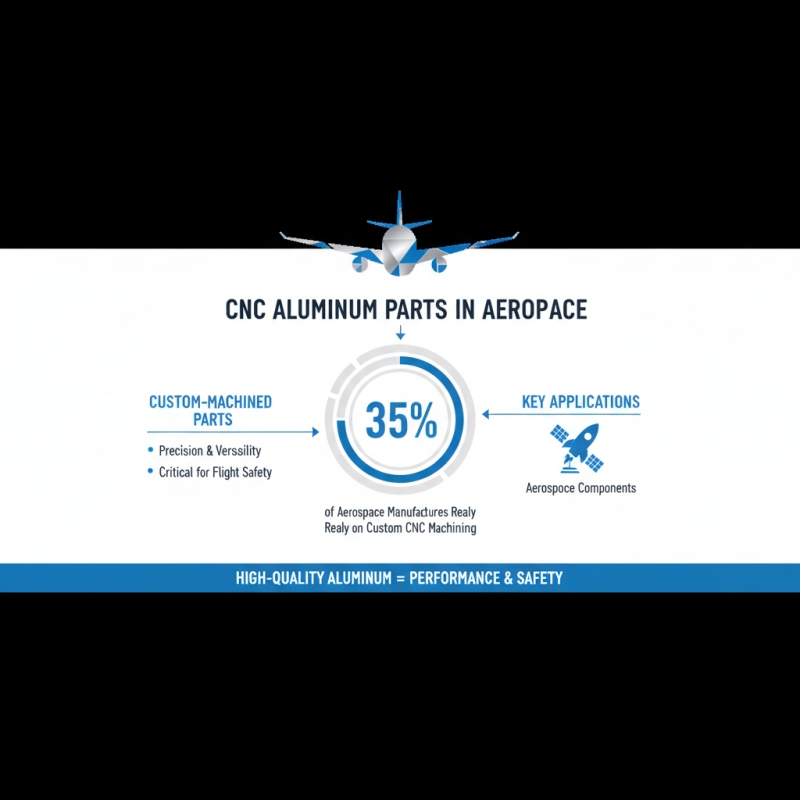

When discussing CNC aluminum parts, various types emerge, each serving unique functions in projects. Custom machined parts are prominent, known for precision and versatility. They often appear in aerospace applications, where accuracy is paramount. Reports indicate that around 35% of aerospace manufacturers rely on custom CNC machining for their components. This demonstrates the significance of high-quality aluminum parts in ensuring flight safety and performance.

Another prevalent type is aluminum housings. These parts protect internal components from environmental factors. Many industries, including electronics and automotive, utilize these housings extensively. Research shows that the global demand for aluminum enclosures is growing at a rate of approximately 8% annually. This reflects the increasing need for durable yet lightweight solutions in modern designs.

However, not every project achieves optimal results. Imperfections can arise during the machining process. For instance, tolerances might not always meet required standards. This can lead to assembly challenges or product failures. Regular feedback and quality checks are essential for improvement. Addressing these flaws ensures continued innovation in CNC machining practices.

When selecting CNC aluminum parts for your project, consider the material's properties and your project's specific needs. Aluminum is lightweight yet strong. It has excellent corrosion resistance, making it suitable for various applications. According to a recent industry report, aluminum parts can reduce overall project weight by 30% compared to steel. This factor is crucial for sectors like aerospace and automotive.

Understanding tolerances is vital too. CNC machining can achieve tight tolerances, often within ±0.005 inches. However, if your project allows for looser tolerances, you might save costs. For prototyping, balancing precision and cost is key. Using lower-grade aluminum could work for initial tests, while high-grade options are better for final versions.

Tip: Always request material samples before finalizing your order. This can prevent costly mistakes. It's also wise to discuss design options with your manufacturer. They might offer insights that could improve your project.

Keep in mind that not all CNC services are equal. Some might promise high quality but deliver subpar results. Thorough research is essential. Visit facilities if possible, and ask for references. This step can help avoid disappointment later on.

When considering CNC aluminum parts for your projects in 2026, identifying reliable manufacturers is crucial. Many suppliers now offer advanced machining services, but not all maintain the same quality standards. It's essential to evaluate their capabilities, production processes, and previous work samples. Red flags include inconsistent product quality and poor communication. Reliable manufacturers should provide transparent timelines and respond to inquiries promptly.

The landscape of CNC machining is ever-evolving. Some suppliers focus on specific industries, such as automotive or aerospace, while others cater to a broader market. Look for those who have invested in modern equipment and skilled personnel. Partnerships may be necessary to find the right fit. However, it’s also vital to reflect on your project needs. Sometimes, settling on a less-than-perfect supplier leads to future complications. Thorough research and critical thinking will guide you in making the best choice for your CNC aluminum parts in 2026.

CNC aluminum parts are evolving. Innovations in technology drive the trends shaping future projects. Precision and efficiency are more important than ever. Lightweight materials enhance performance without sacrificing strength. Engineers and designers are excited about these advancements.

One key trend is the use of advanced machining techniques. They improve the quality and reduce waste. However, many professionals still struggle to keep up with these innovations. Training in new technologies can help bridge this gap.

Tips for your projects: always research the latest tools available. Consider how these innovations can streamline your workflow. Test different techniques to find what works best. Embrace trial and error; it’s not always a smooth path. Demand for CNC aluminum parts will only continue to grow. Stay ahead by adapting to these changes.