In the fast-evolving landscape of modern manufacturing, the reliance on precision and efficiency has propelled the use of CNC machined aluminum parts to the forefront of industrial processes. According to a report by Allied Market Research, the global CNC machining market is poised to reach $100 billion by 2025, driven by the increasing demand for high-quality and customized parts across various sectors, including aerospace, automotive, and consumer electronics. These CNC machined aluminum parts are celebrated not only for their lightweight properties and excellent strength-to-weight ratio but also for their superior machinability and enhanced corrosion resistance. As manufacturers strive for reduced production times and lower operational costs, the ability to produce intricate and high-tolerance components with aluminum through CNC machining has proven to be a game-changer, making it an essential focus for companies aiming to maintain competitive advantage in today's marketplace.

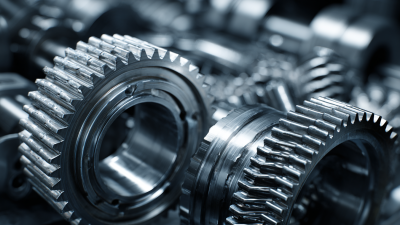

CNC machining has become a cornerstone of modern manufacturing, especially in the production of aluminum parts. One of the primary advantages of CNC machining in aluminum part production is its ability to achieve high precision and consistency, which is crucial for industries such as aerospace and defense. Recent advancements in 5-axis CNC machining technology have further enhanced this capability, allowing manufacturers to create intricate designs with minimal human intervention, leading to reduced error rates and enhanced overall efficiency.

Moreover, the lightweight nature of aluminum combined with the precision of CNC machining makes it an ideal choice for applications in mobile and industrial equipment. Companies are increasingly leveraging this technology to produce aluminum manifolds that cater to the growing demands for lighter, stronger components. This trend not only showcases the advantages of CNC machining in terms of product quality but also highlights its role in facilitating innovation within various sectors, paving the way for new designs and improvements in performance.

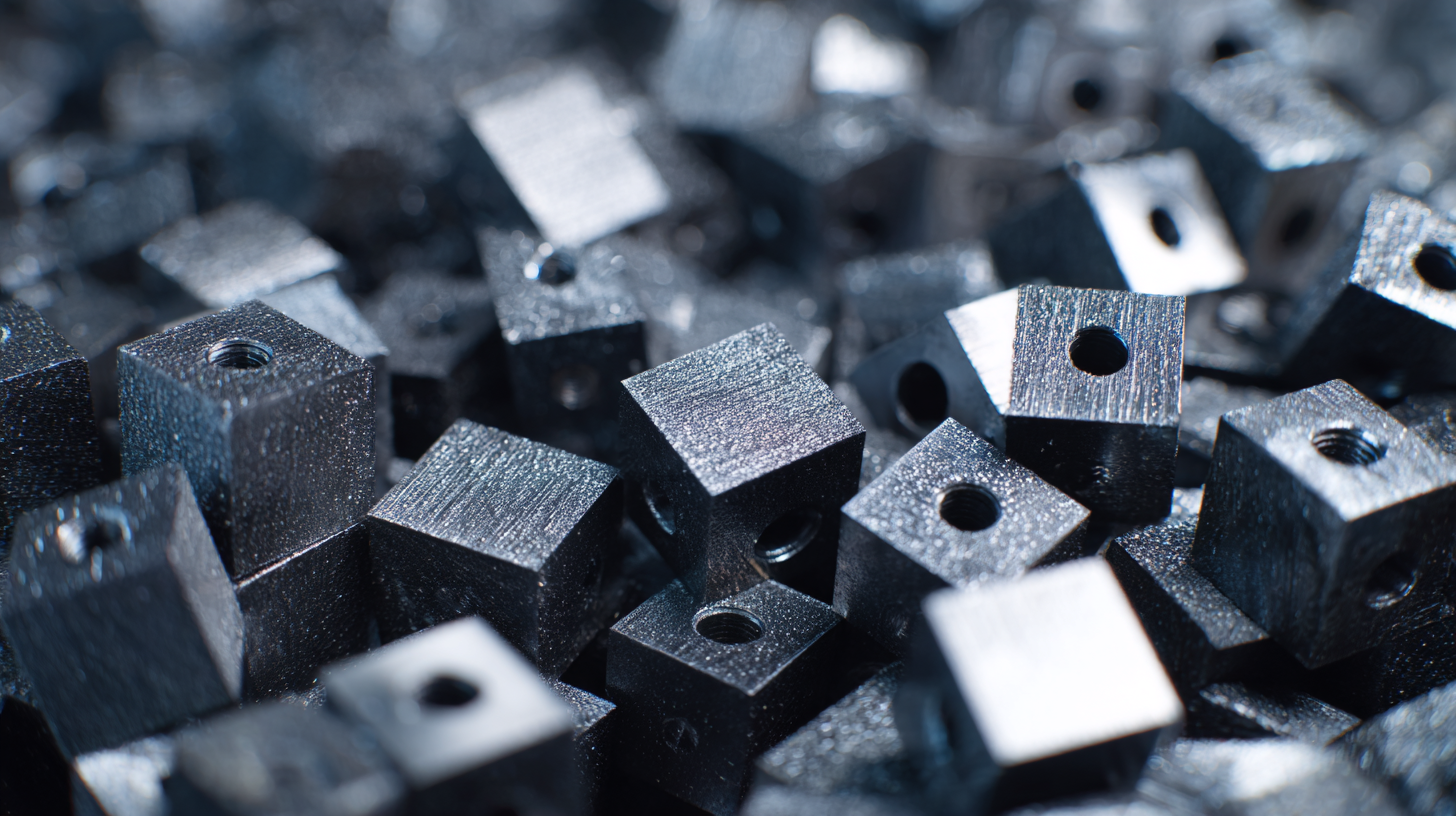

CNC machined aluminum parts have emerged as a cost-effective solution in modern manufacturing, especially when compared to traditional methods like casting or manual machining. The precision offered by CNC technology allows for high-volume production with minimal waste, significantly lowering overall material costs. Additionally, fewer tools and less rework are required, translating to reduced labor expenses and faster turnaround times. This efficiency not only cuts costs but also allows manufacturers to maintain competitive pricing in various markets.

Moreover, the ability to design complex geometries with tight tolerances further enhances the value of CNC machined aluminum. Unlike traditional methods that may struggle with intricate designs, CNC machining provides the flexibility to produce customized parts without incurring significant additional costs. This adaptability is particularly beneficial for industries that require rapid prototyping or small batch production. As a result, businesses can invest in innovative designs while enjoying lower operational costs, making CNC machining a compelling choice for those looking to optimize their manufacturing processes.

| Dimension | CNC Machined Aluminum | Traditional Methods |

|---|---|---|

| Material Cost | $3.00 per lb | $3.50 per lb |

| Setup Time | 1-2 hours | 4-6 hours |

| Production Speed | 200 parts/hour | 80 parts/hour |

| Accuracy Tolerance | ±0.005 inches | ±0.01 inches |

| Waste Material | 5% | 15% |

| Labor Costs | $30/hour | $40/hour |

| Overall Cost per Part | $5 | $8 |

CNC machined aluminum parts have transformed modern manufacturing by providing unparalleled precision and tolerance, which are critical for maintaining high product quality. The ability of CNC machines to replicate designs with extreme accuracy ensures that every component meets the exact specifications required for optimal performance. This precision is particularly vital in industries like aerospace and automotive, where even the slightest deviation can lead to significant failures.

When working with CNC machining, it’s essential to consider factors such as material selection and machining techniques to achieve the best results. **Tips:** Always use high-quality aluminum grades specifically designed for machining to enhance durability. Additionally, regular maintenance of CNC equipment can sustain precision over long production runs, reducing the likelihood of errors in tolerance.

Moreover, consistent tolerances achieved through CNC machining allow manufacturers to reduce waste and lower production costs. This efficiency not only enhances the final product quality but also contributes to sustainable manufacturing practices. **Tips:** Implementing a robust quality control system can further ensure that every part produced aligns with the required tolerances, minimizing the risk of rework and promoting operational efficiency.

CNC machining has transformed modern manufacturing by significantly enhancing the speed of production. By utilizing advanced robotics and computer programs, CNC systems facilitate precise automated processes that minimize human error while maximizing efficiency. According to a report on the Precision Tool Market, the integration of CNC with robotic automation is leading to faster tool changes and improved material handling, directly influencing productivity levels. These advancements underline the crucial role that CNC machining plays in meeting the growing demands of various industries.

In terms of growth, the CNC (Computer Numerical Control) machine market is projected to expand substantially by 2032, reflecting the widespread adoption of digital manufacturing technologies. This shift is fueled by the industry’s need for accelerated production times and improved quality control. As more manufacturers invest in these technologies, the result is a notable increase in output capabilities while concurrently reducing waste. This evolution in manufacturing not only highlights the advantages of CNC machined aluminum parts but also emphasizes how automation continues to redefine operational efficiencies across the sector.

CNC machined aluminum parts are becoming increasingly essential across various industries, thanks to their lightweight and high-strength properties. In the aerospace sector, precision machined aluminum components are used for critical applications in aircraft manufacturing, offering both durability and performance efficiency. Moreover, the automotive industry is experiencing a shift towards aluminum parts to enhance fuel efficiency while maintaining structural integrity, showcasing how these components contribute to environmental sustainability.

Beyond aerospace and automotive, CNC machined aluminum is making strides in the electronics and medical fields. The electronics industry utilizes these parts in the production of housings and heat sinks that require tight tolerances and effective heat dissipation. Similarly, in the medical sector, CNC machined aluminum is utilized for manufacturing surgical instruments and diagnostic equipment, where precision is crucial for safety and effectiveness. As industries continue to recognize the advantages of CNC machined aluminum parts, their application is set to expand, driven by technological advancements and increasing demand for lightweight, high-strength materials.