In the ever-evolving landscape of modern manufacturing, the selection of materials plays a crucial role in optimizing production processes. One material that has gained significant attention is aluminum, renowned for its versatility and superior properties. As John Smith, a leading expert in aluminum engineering, aptly puts it, "The use of aluminum parts in manufacturing not only enhances product durability but also reduces overall weight, leading to performance improvements across various applications."

The adoption of aluminum parts offers numerous benefits that modern manufacturers can leverage to stay competitive. From increased strength-to-weight ratios to exceptional corrosion resistance, aluminum components present an ideal solution in a wide range of industries, including automotive, aerospace, and consumer goods. This lightweight metal contributes significantly to energy efficiency, sustainability, and cost-effectiveness in production, further fueling its popularity among engineers and designers alike.

As we delve into the top ten benefits of using aluminum parts in today's manufacturing processes, we will uncover how this remarkable material is revolutionizing the way products are designed, produced, and delivered, ultimately setting new standards for quality and innovation in the industry.

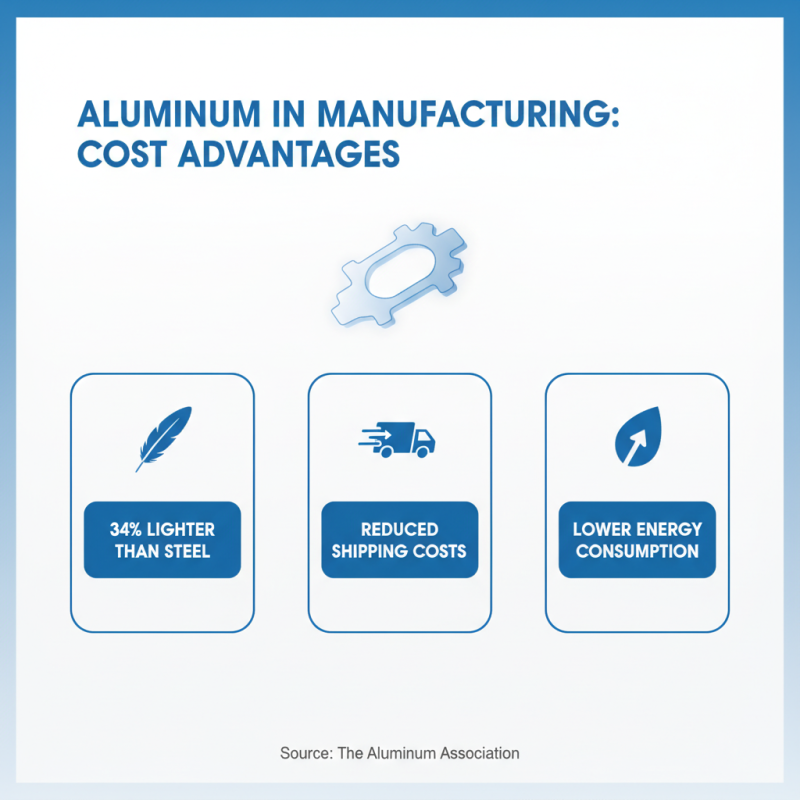

The adoption of aluminum parts in modern manufacturing presents significant advantages, particularly in terms of cost reduction. According to a report from the Aluminum Association, aluminum is approximately 34% lighter than steel, which not only enhances the efficiency of transportation but also lowers associated shipping costs. This weight advantage leads to reduced energy consumption during production and transportation phases, contributing to overall cost savings for manufacturers.

Additionally, aluminum’s excellent malleability and machinability allow for more efficient production processes. A study by the International Journal of Advanced Manufacturing Technology highlights that aluminum components can be fabricated using less energy and time compared to parts made from other materials. This efficiency is further amplified by the fact that aluminum can be recycled indefinitely without loss of quality, which not only cuts down on raw material costs but also reduces waste disposal expenses. With global aluminum recycling rates nearing 75%, manufacturers can capitalize on lower material expenses while promoting sustainability.

The lightweight properties of aluminum play a crucial role in modern manufacturing, significantly impacting production efficiency across various industries. According to a report by the Aluminum Association, aluminum is about one-third the weight of steel, which allows for easier handling and transportation of parts during the manufacturing process. This reduction in weight not only decreases physical exertion needed by workers but also optimizes energy consumption during logistics, ultimately leading to cost savings for manufacturers. An analysis by the International Aluminum Institute highlights that switching to aluminum can improve energy efficiency by up to 20% over traditional materials, making it an attractive option for companies looking to enhance their sustainability efforts.

Moreover, the lightweight nature of aluminum leads to increased design flexibility. Engineers can create more intricate and lightweight structures that were previously unattainable with heavier materials. For instance, aerospace manufacturers are now using aluminum to build airframes that harness its strength-to-weight ratio, improving fuel efficiency and performance. According to a study by McKinsey & Company, the adoption of lightweight materials like aluminum has resulted in up to a 15% reduction in aircraft operating costs, showcasing the tangible benefits of incorporating aluminum into manufacturing processes.

Tip: When considering aluminum for your manufacturing needs, evaluate the specific weight reduction it can offer for your projects and how this may influence overall operational costs. Exploring partnerships with suppliers who specialize in lightweight materials can further enhance your efficiency and innovation. Additionally, regularly assess advancements in aluminum processing techniques to continually improve your production lines.

| Benefit | Description | Impact on Production Efficiency |

|---|---|---|

| Lightweight | Aluminum is significantly lighter than steel, reducing the overall weight of products. | Enhances transportation efficiency and reduces energy costs. |

| Corrosion Resistance | Aluminum forms a protective oxide layer that prevents corrosion. | Increases product lifespan and reduces maintenance costs. |

| Machinability | Aluminum is easier to machine compared to other metals. | Reduces production time and increases throughput. |

| Recyclability | Aluminum can be recycled indefinitely without loss of properties. | Promotes sustainability and reduces material costs. |

| Thermal Conductivity | Aluminum has excellent thermal conductivity, making it ideal for heat-exchange applications. | Improves efficiency in thermal management systems. |

| Aesthetic Appeal | Aluminum has a modern and sleek appearance that can enhance product design. | Attracts customers and improves marketability. |

| Strength-to-Weight Ratio | Aluminum provides a high strength-to-weight ratio compared to many other metals. | Allows designers to innovate with lightweight structures. |

| Electrical Conductivity | Aluminum conducts electricity well, making it suitable for electrical applications. | Improves efficiency in electrical component production. |

| Cost-Effectiveness | Aluminum is often more affordable than other metals, especially in bulk. | Reduces overall production costs. |

| Versatility | Aluminum can be easily alloyed and formed into a variety of shapes. | Allows manufacturers greater flexibility and creativity in product design. |

Aluminum is renowned for its remarkable corrosion resistance, which plays a critical role in the longevity of products manufactured from this versatile metal. When exposed to moisture or environmental factors, aluminum forms a thin, protective oxide layer that inhibits further corrosion. This natural barrier significantly reduces the likelihood of rust or deterioration, making aluminum an ideal choice for various applications, from automotive parts to construction materials. Consequently, products made with aluminum maintain their structural integrity and aesthetic appeal over time, which is especially important in industries where safety and appearance are paramount.

The corrosion resistance of aluminum not only extends the life of individual components but also contributes to overall cost-effectiveness in manufacturing. By reducing the need for frequent replacements and maintenance, aluminum parts minimize downtime and enhance operational efficiency. Furthermore, the lightweight nature of aluminum leads to reduced energy consumption during transportation and installation, further solidifying its role as a sustainable material. As manufacturers continue to seek durable and affordable solutions, the advantages of aluminum, particularly its corrosion resistance, become increasingly valuable in the modern manufacturing landscape.

This chart illustrates the top benefits of using aluminum parts in manufacturing, focusing on their corrosion resistance and overall contribution to product longevity.

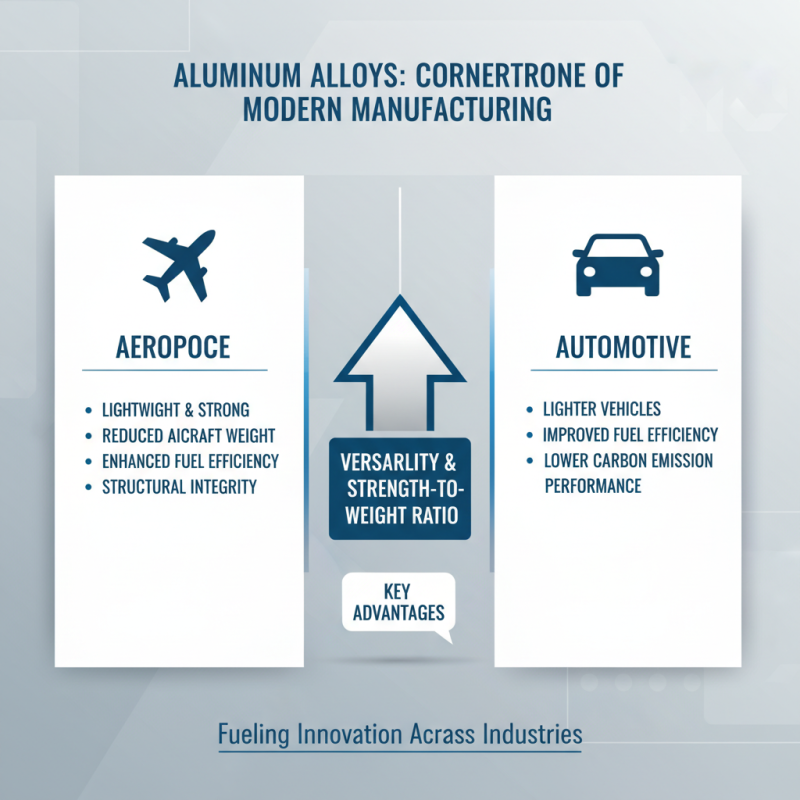

Aluminum alloys have emerged as a cornerstone in modern manufacturing due to their remarkable versatility across various applications. Their lightweight nature combined with excellent strength characteristics makes them an ideal choice for industries ranging from aerospace to automotive. In aerospace, for instance, aluminum alloys reduce overall weight while ensuring structural integrity, enabling more fuel-efficient aircraft designs. In the automotive sector, these alloys contribute to the production of lighter vehicles, enhancing fuel efficiency and reducing carbon emissions without compromising performance.

Another key advantage of aluminum alloys is their corrosion resistance and formability, which allows manufacturers to create complex shapes and parts that are both durable and aesthetically appealing. This attribute plays a crucial role in the construction industry, where aluminum is used in windows, roofing, and facades, bringing both functional benefits and modern design aesthetics. The adaptability of aluminum processing techniques, such as extrusion and casting, further widens its application scope, making aluminum alloys suitable for diverse requirements, from high-volume production runs to custom fabrication. This versatility not only streamlines manufacturing processes but also leads to innovative solutions tailored to specific industry challenges.

The sustainability of aluminum parts plays a significant role in modern manufacturing, aligning with eco-friendly practices that many industries are now adopting. Aluminum is a highly recyclable material, with the recycling process using only 5% of the energy required to produce new aluminum from bauxite ore. According to the Aluminum Association, recycling aluminum can save 90% of the energy and reduce greenhouse gas emissions significantly. This makes aluminum parts not just a choice for efficiency but an environmentally responsible one.

Moreover, the lightweight nature of aluminum contributes to energy savings in transportation, which is critical in reducing the carbon footprint of manufactured goods. For example, the use of aluminum in automotive and aerospace industries has led to substantial weight reductions, improving fuel efficiency and lowering emissions. A report from the International Aluminium Institute highlights that a 10% reduction in vehicle weight can lead to a 6-8% improvement in fuel economy, underlining the beneficial relationship between aluminum usage and sustainability.

Tip: When selecting materials for manufacturing, consider the lifecycle impact of each option. Opting for aluminum can reduce waste and enhance sustainability.

Focusing on eco-friendly practices not only helps in compliance with regulations but also strengthens brand reputation. Businesses increasingly recognize that sustainable manufacturing can lead to cost savings and customer loyalty, leveraging aluminum's benefits for a greener future.

Tip: Keep track of the aluminum sourcing process. Ensure it meets the highest sustainability standards by choosing suppliers committed to responsible mining and recycling practices.