In the realm of manufacturing and construction, the selection of materials plays a pivotal role in determining the durability and performance of end products. Steel parts have emerged as an essential choice for engineers and designers aiming to enhance their projects. According to a recent report by the World Steel Association, steel's remarkable strength-to-weight ratio and versatility account for its substantial presence across various industries, including automotive, aerospace, and construction. This is underscored by the fact that approximately 1.6 billion tonnes of steel are produced globally each year, evidencing its critical role in modern engineering.

When embarking on a new project, choosing the right steel parts can make all the difference. The durability offered by high-quality steel components extends the lifespan of machinery and structures, ultimately leading to reduced maintenance costs and improved operational efficiency. A study published by the American Institute of Steel Construction highlights that steel parts, when properly executed, can withstand high stresses without compromising integrity, making them a popular choice for heavy-duty applications.

As we delve into the 10 best steel parts for your next project, it becomes clear that understanding the distinct advantages and applications of each component is vital for maximizing performance and longevity in any undertaking.

When embarking on a new project that demands durability and performance, selecting the right steel alloy is crucial. Steel alloys vary significantly in their composition and properties, making them suitable for different applications.

For instance, carbon steel is known for its strength and hardness, making it ideal for structural components, while stainless steel, with its corrosion-resistant properties, is perfect for projects exposed to harsh environments.

Understanding the specific requirements of your project can help you select the most appropriate alloy.

Another important factor to consider is the heat treatment of the steel. Alloys like tool steel can be heat-treated to enhance their hardness and wear resistance, which is essential for tools and high-stress applications.

On the other hand, low-alloy steels offer a balance between strength, ductility, and toughness, making them versatile for various engineering applications.

By assessing the mechanical properties required for your project, such as tensile strength and fatigue resistance, you can make an informed choice that enhances both the durability and performance of your final product.

When selecting steel parts for your next project, understanding the essential mechanical properties is crucial for ensuring durability and performance. One of the most significant properties to consider is tensile strength, which indicates the material's ability to withstand maximum stress without fracturing. A higher tensile strength allows for the creation of components that can resist deformation under heavy loads, making them suitable for high-stress applications.

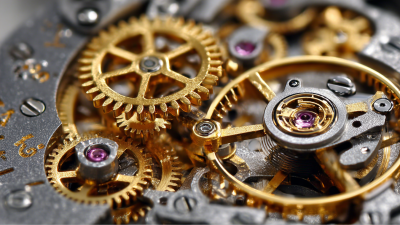

Another vital factor is hardness, the measure of a material's resistance to localized plastic deformation. Hard steel parts are ideal for applications requiring wear resistance, such as gears and cutting tools. Additionally, toughness, which reflects a material's ability to absorb energy and resist cracking, is necessary for components subjected to dynamic loads or impact. Selecting steel parts with the right balance of these mechanical properties can significantly enhance the performance and longevity of your project.

When selecting steel parts for any project, the importance of corrosion protection cannot be overstated. According to the National Association of Corrosion Engineers (NACE), corrosion costs the U.S. economy over $276 billion annually, highlighting the need for effective coating solutions. A well-chosen coating not only enhances the steel's durability but also significantly extends its lifespan, making it a vital consideration for any engineering endeavor.

Among the top coating options available, powder coating stands out for its durability and environmental resistance. Its application creates a tough, protective layer that can withstand harsh environmental conditions, making it ideal for outdoor projects. Additionally, epoxy coatings are renowned for their excellent adhesion and chemical resistance, which is crucial in industrial settings where exposure to corrosive substances is common. A recent report from Technavio notes that the global powder coating market is expected to grow by 6% annually, underlining the growing recognition of these advanced protective coatings among industry leaders. As professionals invest in high-performance coatings, they are not only improving the longevity of steel components but also reducing maintenance costs and enhancing their overall project performance.

| Part Name | Material Type | Coating Type | Corrosion Resistance | Applications |

|---|---|---|---|---|

| Steel Shaft | Carbon Steel | Galvanization | High | Machinery, Automotive |

| Steel Plate | Stainless Steel | Powder Coating | Very High | Construction, Architecture |

| Steel Rod | Alloy Steel | Chrome Plating | Moderate | Manufacturing, Tooling |

| Steel Tube | Mild Steel | Hot-Dip Galvanization | High | Piping, Fencing |

| Steel Beam | Structural Steel | Epoxy Coating | High | Heavy Construction, Bridges |

| Steel Frame | Carbon Steel | Zn-Ni Coating | Very High | Building Frames, Support Structures |

| Steel Fasteners | Stainless Steel | Passivation | High | Machinery, Assembly |

| Steel Spring | High Carbon Steel | Black Oxide | Moderate | Automotive, Electronics |

| Steel Chain | Carbon Steel | Oil Coating | Low | Transport, Lifting |

| Steel Cable | Stainless Steel | Polymer Coating | High | Maritime, Construction |

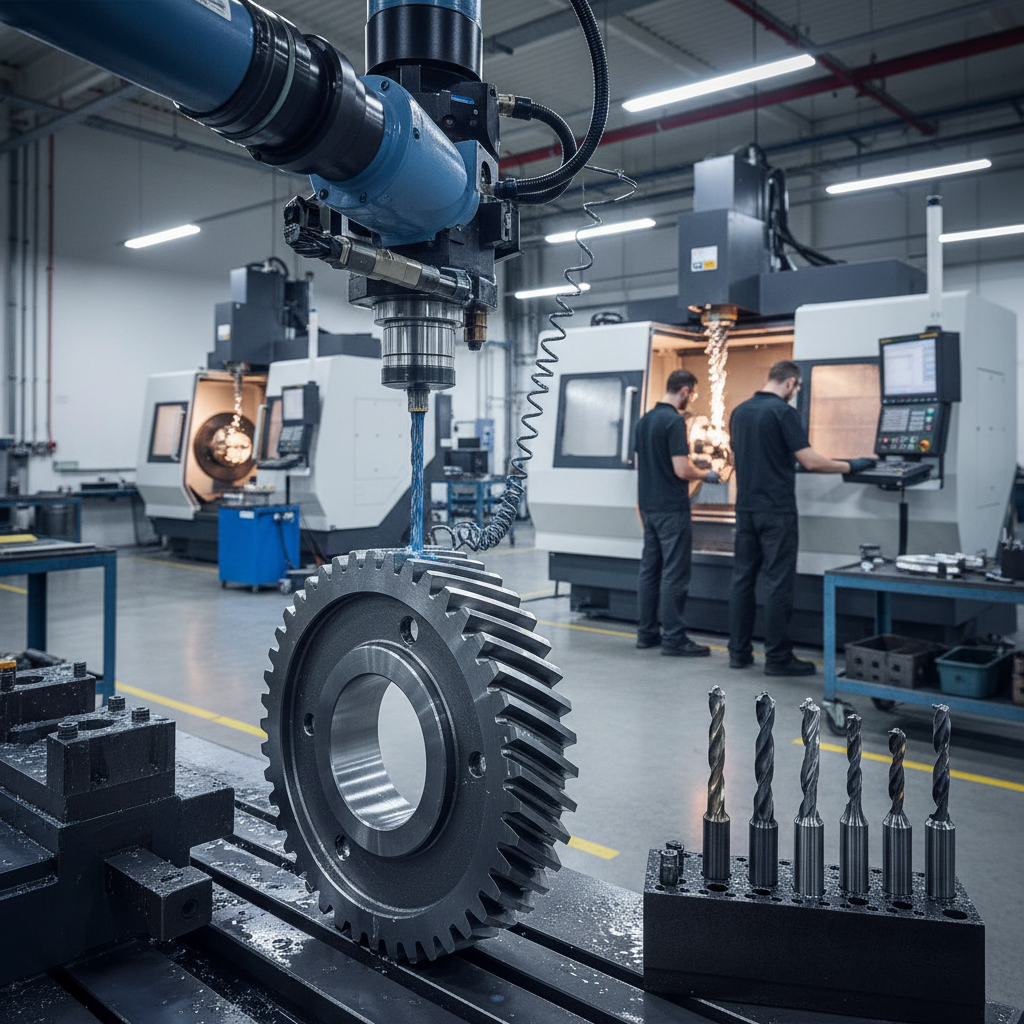

When machining and fabricating steel components, adhering to best practices can significantly enhance both durability and performance. The selection of the appropriate machining tools is crucial; using high-speed steel (HSS) or carbide tools ensures efficient material removal and preserves the quality of the steel. It's important to maintain the correct cutting speeds and feeds tailored to the specific type of steel being used, as this can prevent wear on tools and reduce the risk of defects in the final product. For instance, choosing the right coolant is also essential; it helps to dissipate heat and prolongs the life of the cutting tools while ensuring clean cuts.

In addition to tool selection, proper planning during the fabrication process cannot be overlooked. Techniques such as strategic part orientation and prioritizing cuts based on grain direction can lead to stronger finished products. Furthermore, implementing quality control measures throughout the machining process, such as regular inspections and using precision measuring instruments, guarantees that each component meets the required specifications. By integrating these best practices, manufacturers can optimize their steel components' overall strength and performance, making them suitable for demanding applications.

When embarking on a project that requires steel parts, selecting the right supplier is crucial to ensure both durability and performance. According to a recent report by the Steel Market Development Institute, the use of high-quality steel can improve longevity and effectiveness in various applications, ranging from construction to manufacturing. Therefore, finding reputable steel parts suppliers who adhere to strict quality standards and certifications, such as ISO 9001, is essential. This ensures that the materials provided not only meet the specific engineering requirements but also contribute to the overall safety and performance of the project.

Moreover, it’s important to consider the supplier's track record in the industry and their ability to provide custom solutions. A study conducted by the American Institute of Steel Construction revealed that companies sourcing their materials from established suppliers experienced a 20% reduction in project delays due to product failures. Thus, researching supplier capabilities, client testimonials, and adherence to industry regulations can significantly impact your project's success. Additionally, leveraging platforms like ThomasNet or SupplierSelect can help identify reliable partners that align with your project needs.