In the realm of manufacturing, the materials chosen for production can significantly influence the quality and performance of the final product. Among these materials, brass parts stand out for their exceptional properties and versatility. Composed primarily of copper and zinc, brass parts offer a unique combination of durability, corrosion resistance, and machinability, making them an indispensable choice for a wide array of applications. From automotive components to electronic devices, the integration of brass parts enhances both functionality and longevity, ensuring that manufactured goods meet the demands of today's market.

Brass parts are not only valued for their physical characteristics but also for their aesthetic appeal. The lustrous golden hue of brass can elevate the design of products, adding a touch of sophistication to various devices and machinery. As manufacturers strive for an optimal balance between performance and visual impact, the use of brass parts continues to gain traction. Furthermore, the ease of fabrication associated with brass allows for intricate designs and precision engineering, which are critical in meeting the specialized requirements of modern manufacturing projects. Overall, the essential role of brass parts in manufacturing cannot be overstated, as they contribute to enhancing quality, performance, and design across industries.

Brass parts play a crucial role in manufacturing processes across various industries due to their exceptional properties, including durability, corrosion resistance, and excellent machinability. According to the Brass and Copper Alloys Market report by ResearchAndMarkets.com, the global market for brass alloys is expected to grow significantly, driven by increasing demand in sectors such as automotive, plumbing, and electrical components. These materials not only enhance the longevity of products but also reduce maintenance costs, making them a preferred choice in high-performance applications.

In addition to their physical attributes, brass parts contribute to energy efficiency and sustainability in manufacturing. The Department of Energy reports that utilizing brass can improve the overall efficiency of mechanical systems due to its ability to withstand wear and tear while maintaining performance. Furthermore, as industries continuously strive for eco-friendliness, the recyclability of brass presents an additional advantage. According to the International Copper Association, approximately 90% of all brass produced is recycled, promoting a circular economy and minimizing waste. This makes brass an ideal material for manufacturers committed to sustainable practices.

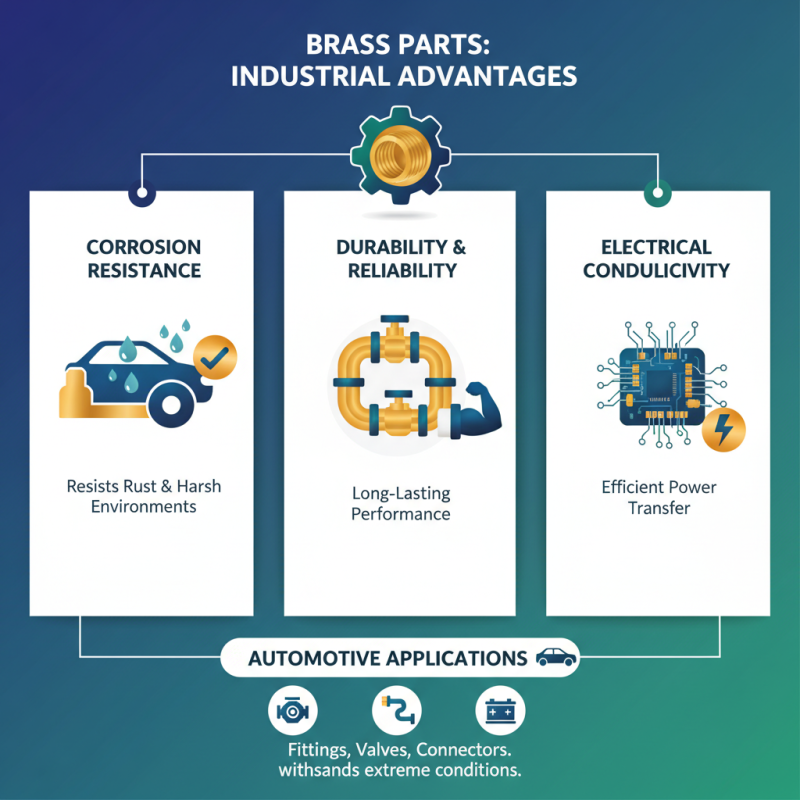

Brass is a popular choice in various industrial applications due to its remarkable properties that enhance performance and durability. One of the key advantages of brass is its excellent corrosion resistance. Unlike many metals, brass can withstand harsh environments, making it ideal for components used in plumbing, marine, and outdoor settings. This resistance to corrosion extends the lifespan of parts and reduces maintenance costs, providing manufacturers with a reliable long-term investment.

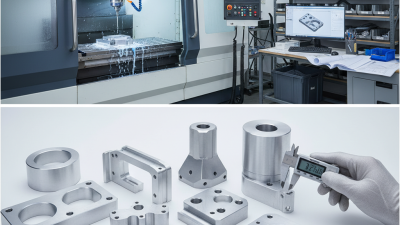

Another significant advantage of brass is its machinability. Brass can be easily cut, shaped, and formed, allowing manufacturers to produce intricate designs and components with precision. This machinability not only speeds up the production process but also results in minimal material waste, contributing to a more efficient manufacturing operation. Additionally, brass fittings and connectors have superior thermal and electrical conductivity, making them essential in electronics and electrical applications where performance is crucial. Overall, the combination of durability, ease of manufacturing, and conductivity underscores the importance of brass parts in various industrial sectors.

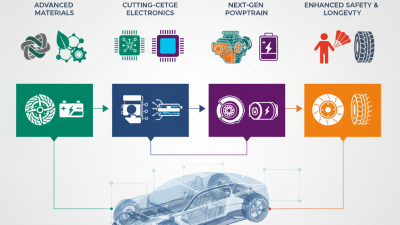

Brass parts play a pivotal role across various industries owing to their unique properties such as corrosion resistance, durability, and excellent conductivity. In the automotive industry, brass components are commonly used in fittings, valves, and connectors due to their ability to withstand harsh environments while providing reliable performance. The non-ferrous nature of brass helps prevent rust, making it ideal for both exterior and interior applications within vehicles.

In the plumbing sector, brass fittings and fixtures are essential for creating leak-proof seals. The material's strength and resistance to wear make it a preferred choice for piping systems. Additionally, in the electronics industry, brass is often utilized in connectors and housings, where its conductivity allows for efficient transmission of signals without significant interference. This versatility underscores the significance of brass parts, demonstrating their indispensable role in enhancing the efficiency and reliability of products across diverse industrial applications.

When selecting brass parts for manufacturing needs, it's crucial to consider various factors that align with your specific applications. One of the primary criteria is the brass alloy composition. Different brass alloys, such as yellow brass or red brass, offer varying levels of strength, corrosion resistance, and machinability. Depending on the project requirements, identifying the right alloy can significantly impact the durability and performance of the final product.

Another important factor to consider is the size and dimensional accuracy of the brass parts. Precision components may require stringent tolerances, which dictate the manufacturing processes that can be employed, such as CNC machining or die casting. Understanding the production method that will be used can guide the selection of brass parts that not only fit well in the assembly but also enhance the overall functionality. Additionally, analyzing the environmental conditions in which the components will operate, such as temperature and exposure to chemicals, will further inform the selection process, ensuring the longevity and reliability of the brass parts used in your manufacturing projects.

| Criteria | Description | Importance | Applications |

|---|---|---|---|

| Corrosion Resistance | Brass exhibits good resistance to corrosion, particularly in marine environments. | High | Marine hardware, plumbing fittings |

| Machinability | Brass can be easily machined, allowing for intricate designs and precision parts. | Medium | Automotive components, electrical connectors |

| Ductility | Brass can be easily drawn into wires or formed into shapes without breaking. | High | Decorative items, musical instruments |

| Aesthetic Appeal | Brass has a distinctive gold-like appearance that is visually appealing. | Medium | Architecture, trophies, musical instruments |

| Conductivity | Brass has good electrical and thermal conductivity compared to other metals. | High | Electrical components, heat exchangers |

Brass components have become increasingly vital in manufacturing due to their sustainability and longevity. Composed primarily of copper and zinc, brass is not only durable but also resistant to corrosion, which significantly extends the lifespan of products made from this material. This resilience makes brass an ideal choice for a wide variety of applications, from plumbing fittings to electronic connectors. By utilizing brass, manufacturers can reduce the frequency of replacements, thus minimizing waste and supporting more sustainable production practices.

The recyclability of brass further enhances its value in a sustainable manufacturing environment. Unlike many other materials, brass can be recycled repeatedly without losing its quality. This characteristic not only conserves natural resources but also reduces energy consumption associated with the production of new materials. In a world increasingly focused on environmental responsibility, brass stands out as a smart choice for manufacturers looking to align their operations with sustainable principles. By choosing brass components, manufacturers not only support longer product lifespans but also contribute positively to the broader ecological footprint of their production processes.