When considering materials for your next project, aluminum parts offer a compelling option. They are lightweight yet strong, making them ideal for various applications. According to a report by the Aluminum Association, the global aluminum market is projected to reach $250 billion by 2025. This growth highlights the increasing reliance on aluminum components across industries.

Renowned expert Dr. Emily Carter emphasizes the versatility of aluminum. She states, "Aluminum parts not only reduce weight but also enhance performance and sustainability." This makes them an attractive choice for manufacturers aiming to innovate and improve efficiency. However, challenges exist in terms of machining and surface treatments that must be addressed.

As we explore the reasons to choose aluminum parts, it's important to acknowledge some downsides. While aluminum is corrosion-resistant, certain environments can still be problematic. Understanding these factors becomes crucial when deciding on materials for specific applications. Balancing the benefits and potential limitations will lead to a more informed choice in your next project.

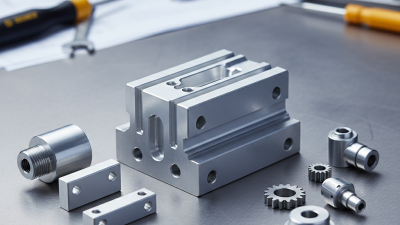

Aluminum parts have become increasingly popular in various manufacturing projects. One key benefit of using aluminum is its lightweight nature. This property allows for easy handling and transportation, reducing costs and labor time. Additionally, aluminum is highly malleable. It can be easily formed into complex shapes without breaking. This versatility is a significant advantage in many designs.

Another critical benefit is aluminum's resistance to corrosion. When exposed to moisture, it does not easily rust. This quality makes it suitable for outdoor applications and industries like automotive and aerospace. However, the production process of aluminum can be energy-intensive. It's worth considering the environmental impact. Not all aluminum used is recycled, which could raise sustainability concerns.

Furthermore, aluminum offers excellent thermal and electrical conductivity. This feature is particularly beneficial in electronics and heat dissipation applications. However, one must be cautious about its cost. While generally affordable, prices can fluctuate based on market demand. These factors must be weighed carefully to ensure the project remains cost-effective and sustainable.

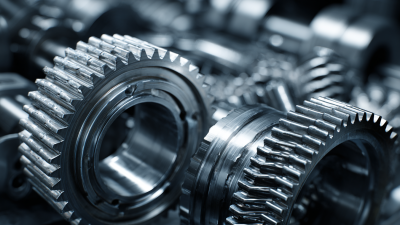

Aluminum has become a popular choice for many projects due to its impressive durability and strength. This lightweight metal is resistant to corrosion, making it ideal for outdoor use. In demanding environments, aluminum parts hold up well, ensuring longevity. Their ability to withstand varying temperatures is a significant advantage too.

Despite these benefits, some may underestimate aluminum’s strength. It is not as heavy as steel but can perform similarly under certain conditions. This aspect makes it an excellent option for projects requiring weight savings without sacrificing structural integrity. Proper alloy selection further enhances its strength.

However, aluminum isn’t perfect. It can be prone to scratching or denting under impact compared to harder metals. Yet, with careful handling and design, these issues can become minor concerns. Using protective coatings may also extend the life of aluminum parts. Overall, its balance of durability and weight makes aluminum a smart choice for innovative projects.

This bar chart compares the tensile strength of aluminum against other common materials such as steel, copper, and titanium. Aluminum shows considerable strength, making it a durable choice for various applications.

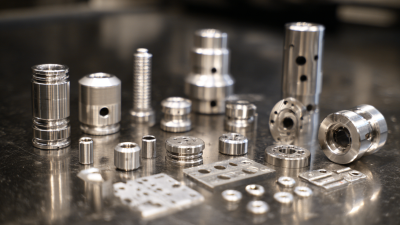

Aluminum is known for its lightweight nature. This attribute makes it a popular choice for various projects. From aerospace to automotive applications, aluminum parts reduce overall weight.

Lighter materials can improve fuel efficiency and performance. This is especially true for vehicles that need speed and agility.

When considering aluminum, think about its strength. Despite being light, aluminum is strong. It can withstand harsh conditions. This makes it perfect for outdoor applications, like construction and marine settings. However, aluminum can be prone to corrosion. Proper treatments are essential to enhance durability.

Tips: Always assess the environment where the parts will be used. Is moisture present? Look for coatings that protect against rust. Another tip is to weigh the cost versus performance. While aluminum might be pricier upfront, its longevity can save money in the long run. Choose wisely and ensure the material fits your specific needs.

Aluminum is known for its remarkable corrosion resistance in various environments. Extensive studies, including those from the Aluminum Association, show aluminum can withstand extreme conditions. In saltwater, it exhibits a natural protective layer that slows down corrosion. This makes it ideal for coastal applications, where salt exposure is a concern.

In harsh industrial settings, aluminum proves its durability. Reports indicate that aluminum parts can last three times longer than steel counterparts in similar environments. This is vital in industries like construction and marine applications. Even with some imperfections, aluminum adapts well. However, it’s essential to account for the specific alloy used, as not all types offer the same level of resistance.

Despite its advantages, challenges remain. Aluminum can suffer from pitting corrosion when exposed to certain chemicals. Thus, careful material selection and treatment methods are necessary. Assessing the project requirements and environment is crucial. Properly coated aluminum can enhance performance further, but oversight is always a risk. Balancing these factors can lead to better project outcomes.

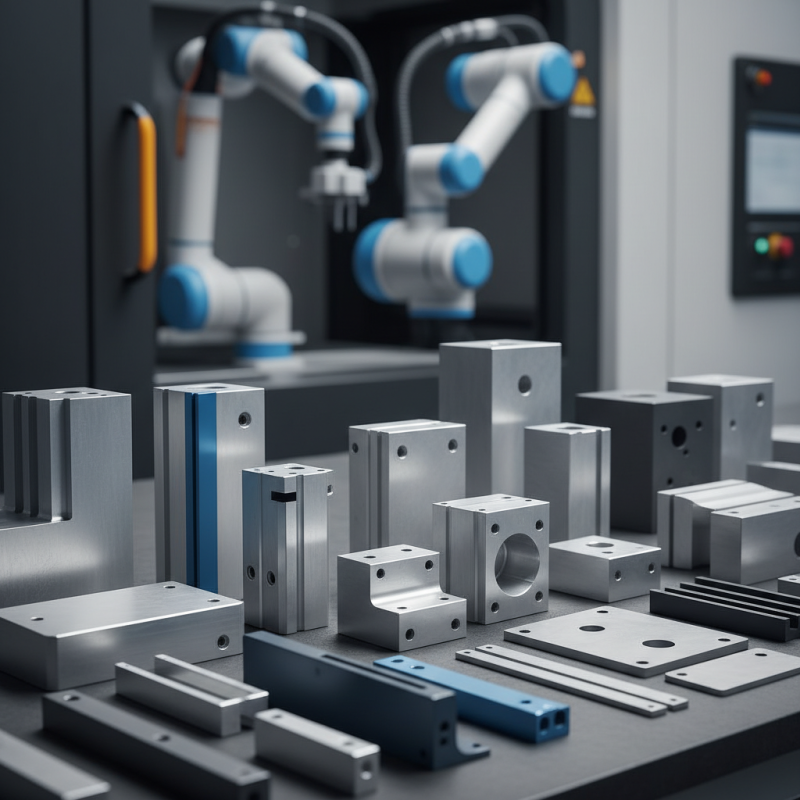

When considering materials for your next project, aluminum stands out as a cost-effective choice. Over time, aluminum parts can significantly reduce maintenance costs. This lightweight material often leads to lower shipping fees and easier handling during assembly. In many cases, this simple factor influences budget allocations in a positive way.

Aluminum's durability and resistance to corrosion extend the life of components. While it may seem pricier initially, the long-term savings in replacements and repairs add up. Think about the energy efficiency, too. Aluminum can enhance performance, which reduces energy consumption over the product's lifespan. Such benefits are not always recognized at first glance. However, they play a crucial role in overall project costs.

Despite the advantages, it's vital to acknowledge some challenges. Fabrication can be tricky. Experienced professionals are necessary to ensure quality work. Additionally, not all aluminum alloys perform equally. Researching the right type is crucial to harnessing its benefits effectively. As you weigh options, consider both the immediate and future implications of your materials choice.

| Metric | Aluminum | Steel | Plastic |

|---|---|---|---|

| Initial Material Cost (per kg) | $2.50 | $1.00 | $1.20 |

| Weight (kg/m3) | 2700 | 7850 | 950 |

| Recyclability (%) | 100% | 100% | 50% |

| Corrosion Resistance (years) | 25+ | 10 | 5 |

| Long-Term Maintenance Cost (per year) | Low | Moderate | High |

| Typical Applications | Aerospace, Automotive, Construction | Construction, Heavy Machinery | Packaging, Consumer Goods |