When it comes to selecting steel parts, the right choice can greatly impact your project's success. Expert John Smith, a leading figure in the steel industry, once said, "Choosing the right steel parts is crucial for durability and performance." This highlights the importance of making informed decisions.

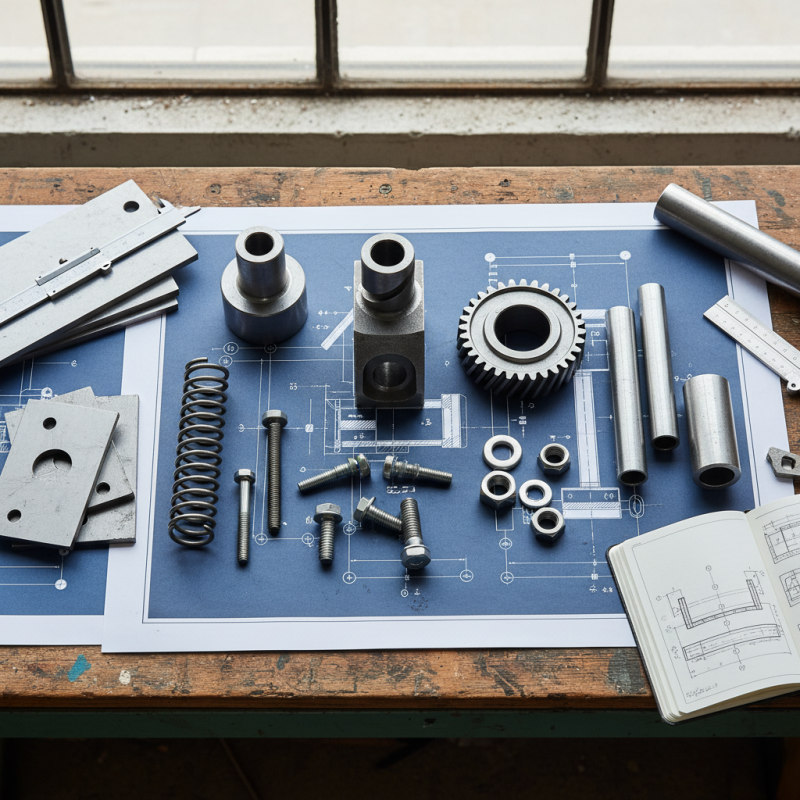

Understanding the specifications of steel parts is vital. They must suit the specific conditions of your project. Consider the load requirements and environmental factors. Not all steel types are equal. For instance, carbon steel works well for many applications, but it may not withstand corrosion in harsh environments.

It's essential to weigh the pros and cons. Some steel parts may promise strength but could come at a higher cost. Reflecting on these details can lead to better long-term outcomes. Your choices should align with the project's goals and budget. In the world of steel parts, small mistakes can lead to significant setbacks.

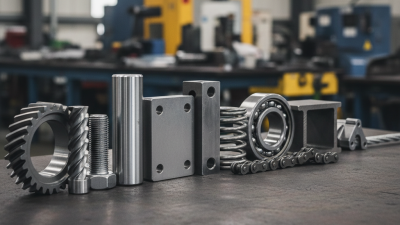

When selecting steel parts, it's crucial to understand the various types available. Each type has unique properties and uses. Carbon steel is one of the most common options. It offers strength and durability, making it suitable for construction projects. However, it can rust easily without proper protection. This is something to keep in mind.

Another popular option is stainless steel. Its resistance to corrosion makes it an excellent choice for outdoor applications. Stainless steel can be more expensive than carbon steel. But the trade-off might be worth it for longevity and reduced maintenance.

Alloy steel combines several elements to enhance performance. It's often used in high-stress applications, like machinery. On the downside, its complexity can sometimes lead to higher costs. It’s essential to assess the specific needs of your project. Ultimately, choosing the right steel part requires careful consideration of these factors.

Selecting the right steel parts for your project requires careful consideration. Different applications demand various steel grades and properties. For example, structural steel, often used in construction, must have high tensile strength to support heavy loads. According to the American Institute of Steel Construction, using the right grade enhances safety and durability.

Corrosion resistance is another crucial factor. Outdoor applications need steel that can withstand environmental elements. Stainless steel is often recommended, as it contains nickel and chromium, which improve resistance to rust. Reports suggest that using corrosion-resistant steel can increase the lifespan of structures by up to 50%. However, this may come at a higher initial cost.

You may encounter challenges in sourcing quality steel that meets specific requirements. It's not uncommon to find discrepancies in standard specifications. Always verify the certificates of compliance from suppliers. Investing time in understanding material properties can save significant costs and ensure project success.

| Factor | Description | Considerations |

|---|---|---|

| Material Grade | Determines strength, ductility, and corrosion resistance. | Choose based on project requirements and environmental factors. |

| Thickness | Affects durability and resistance to loads. | Consider load-bearing requirements and safety factors. |

| Finish | Influences aesthetic appeal and resistance to rust. | Select based on exposure to humidity and corrosive elements. |

| Fabrication Process | Methods include cutting, welding, and machining. | Choose processes compatible with project timeframe and budget. |

| Industry Standards | Ensures quality and safety for the final product. | Verify compliance with relevant regulations for your project. |

When selecting steel parts for your projects, evaluating strength and durability is key. Different projects have varying demands. Some applications require high tensile strength, while others focus on impact resistance. Assessing these specifics will help guide your material choice.

It's vital to analyze the environmental conditions your steel components will face. Components exposed to moisture need corrosion-resistant alloys. On the other hand, parts in high-temperature settings must maintain their integrity. Testing samples before full-scale production can reveal unanticipated weaknesses. Embrace potential flaws in your design to improve future iterations.

Consider consulting with engineers or professionals who understand steel properties. Their insights can save you from costly mistakes. However, trust your instincts as well. Sometimes, the best solutions emerge from hands-on experiments. Reflect on past projects, learn from errors, and be open to adjustments as you make decisions about steel parts.

When budgeting for steel parts, consider the full scope of costs. Material prices are only one piece of the puzzle. You should also factor in labor, shipping, and any processing fees. Sometimes, the best deal upfront can hide additional expenses down the line. Always ask for a detailed quote.

One tip is to compare multiple suppliers. Prices can vary significantly. A slightly higher price may offer better quality or service. Inspect the suppliers’ reputations as well. Check online reviews and seek references. A bargain can turn into a costly mistake if the product fails.

Another suggestion is to plan for potential waste. Steel can be unforgiving. Cutting mistakes happen, and the cost of excess material can add up. It’s wise to overestimate your needs to avoid running short. However, over-ordering can also tie up your funds. Balancing these factors requires careful deliberation. Consider all angles before committing.

Choosing the right suppliers for steel parts can significantly impact project quality. A study by the Steel Market Development Institute revealed that about 70% of project delays stem from sourcing issues. Therefore, sourcing from reliable suppliers is crucial. Look for suppliers with a proven track record in the market. They should provide certifications and quality assurance that demonstrate their compliance with industry standards.

Engage in conversations with potential suppliers. Ask about their sourcing practices and quality control measures. Transparency is key. Some suppliers might hesitate to share their processes; this can be a red flag. Quality steel parts should meet specific specifications. Check if they adhere to standards such as ISO or ASTM. This ensures that the materials will perform as expected in your projects.

Additionally, analyze supplier reviews and client testimonials. A report from the American Society for Testing and Materials indicates that companies that actively seek feedback from clients improve their sourcing outcomes by 50%. Don’t shy away from asking previous clients about their experiences. Gathering insights can guide you in your selection process. Remember, every project deserves reliable components. Your choice of suppliers can make or break your project’s success.