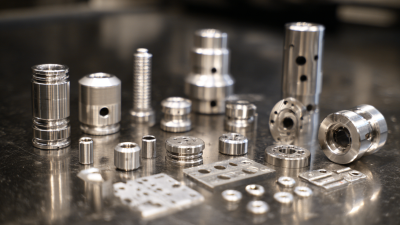

Choosing the right aluminum parts for your project can be daunting. Industry expert John Smith states, "The quality of aluminum parts makes or breaks a project." This highlights the importance of selecting the best components.

Understanding your project's specific needs is essential. Aluminum parts vary widely in shape, size, and application. Not all parts will suit every project. Common mistakes include opting for cheaper options that compromise quality. This could lead to failures down the line.

Moreover, consider the source of your aluminum parts. Reliable manufacturers offer consistency and durability. When in doubt, consult professionals who understand these differences. Their experience can guide you to make informed choices. Your project's success often hinges on these critical decisions.

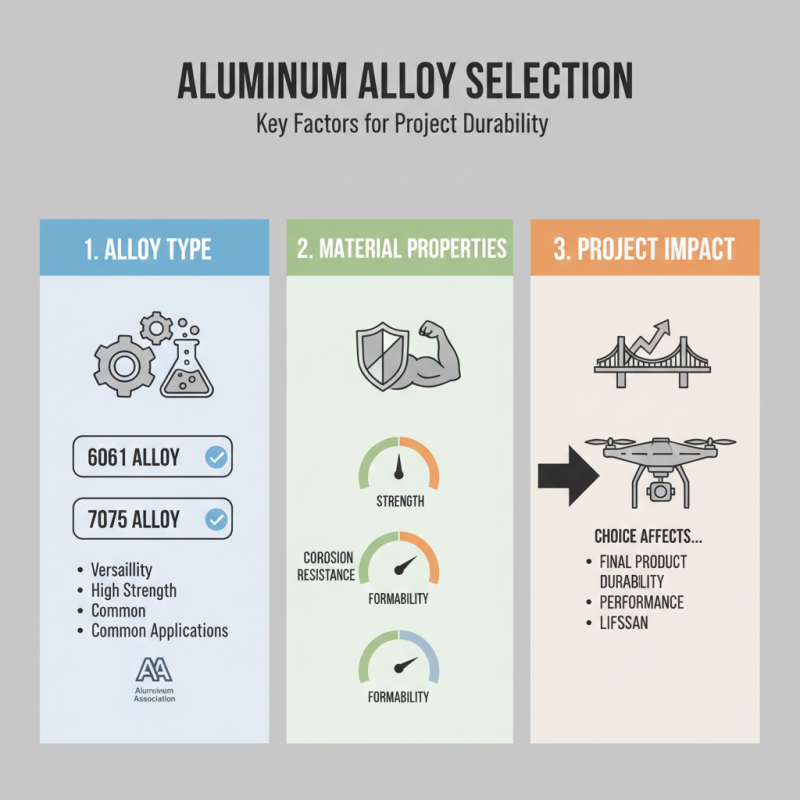

Selecting the right aluminum alloy is crucial for any project. Aluminum alloys come in various types, each offering unique properties. The two main categories are wrought and cast alloys. Wrought alloys are generally stronger and more ductile. They are often used in applications requiring high strength and formability. In contrast, cast alloys are easier to shape and are perfect for complex designs.

The most common aluminum alloys include 6061 and 7075. According to the Aluminum Association, 6061 is highly versatile. It boasts good corrosion resistance and weldability. This makes it suitable for structural applications and automotive parts. On the other hand, 7075 is known for its exceptional strength. It’s often used in aerospace applications. However, it is less resistant to corrosion. This trade-off can be critical depending on end-use conditions.

Understanding the specific requirements of your project can make or break your choice. Consider factors like weight, corrosion resistance, and fatigue strength. Even minor decisions can impact overall performance. There’s no one-size-fits-all solution. Carefully evaluate your project needs before selecting an aluminum alloy. Rushing this process often leads to costly mistakes.

When selecting aluminum parts for your project, several key factors must be considered. The alloy type is crucial. Aluminum alloys vary in strength, corrosion resistance, and formability. According to the Aluminum Association, the 6061 and 7075 alloys are often favored for their versatility and strength. The choice of alloy can significantly affect the durability of the final product.

The intended application of the aluminum parts also matters. Parts exposed to harsh environments require higher corrosion resistance. A report by ASTM International highlights that choosing the correct surface treatment can enhance the longevity of aluminum components. Anodizing or coating can protect against wear and corrosion, extending the life of the parts.

Cost is another important factor. While opting for cheaper alternatives might seem tempting, it can lead to higher expenses over time. A study by the U.S. Department of Energy indicates that investing in quality aluminum parts can reduce maintenance and replacement costs. Balancing cost with performance is vital for project success. Each decision should reflect a careful evaluation of these elements to ensure that your project achieves its goals without compromising quality.

When assessing the cost-effectiveness of aluminum compared to other materials, it's essential to look at weight, durability, and processing costs. Aluminum is lightweight, which lowers shipping costs. Reports suggest that aluminum parts can reduce overall project weight by 30%, leading to significant savings in transport. However, the initial cost of aluminum can be higher than steel or plastic.

Manufacturers often choose aluminum for its recyclability. Almost 75% of all aluminum ever produced is still in use. This reflects a trend toward sustainability. It's crucial to consider life cycle costs, not just upfront expenses. Aluminum might offer lower maintenance costs over time, which can justify its initial price.

Tip: Always evaluate different suppliers to find competitive pricing. Look for locally sourced materials to minimize costs. Additionally, consider the specific needs of your project. Choosing the right alloy can enhance performance and reduce waste. This is an area where many projects fall short. Using a less suitable alloy can lead to higher long-term costs.

Selecting aluminum parts for your project involves understanding industry standards and certifications. These factors ensure quality and performance. Look for certifications like ISO 9001, which indicates a commitment to quality management. Another important certification is ASTM, which provides testing and material specifications for aluminum.

Quality aluminum components should meet specific requirements. For instance, consider the alloy type for your application. Alloys like 6061 and 7075 have different strengths and are suited for various uses. The anodization process can also enhance durability. It creates a protective layer, preventing corrosion and wear.

However, navigating these standards can be challenging. Not all suppliers conform to the same regulations. Some may offer vague certifications or none at all. It’s crucial to ask for documentation. Verify the claims they make about their products. You may face complexities in selecting the right part. Take time to research and consult knowledgeable sources. This effort can ultimately save you from costly mistakes.

Aluminum parts have a wide range of applications in various sectors, from aerospace to automotive. In aerospace, lightweight materials are crucial. Data from the Aluminum Association reveals that aluminum makes up about 75% of the airframe weight of commercial aircraft. This reduction in weight leads to significant fuel savings. However, the challenge lies in ensuring the durability of these components under extreme conditions.

In the automotive industry, aluminum's role is increasing. According to a report by the International Aluminum Institute, around 30% of vehicles produced in 2021 contained aluminum parts. These components enhance fuel efficiency and reduce overall vehicle weight. Yet, manufacturers face hurdles in recycling these materials effectively. Not all aluminum types are easily recyclable, which affects sustainability initiatives.

Different industries demand different specifications. Aerospace components require stringent quality checks, while automotive parts may prioritize cost-efficiency. It can be overwhelming to navigate these requirements. Engineers often feel pressured to meet deadlines, leading to compromises in quality or material choice. Balancing weight, strength, and cost in aluminum parts is a constant challenge that requires careful consideration.