In the dynamic world of manufacturing and design, selecting the right materials is crucial, particularly when it comes to aluminum components. The precision and versatility of Aluminum Parts make them a favorite among engineers and designers alike. As industry expert, Dr. John Smith, a leading figure in materials engineering, famously stated, "The right aluminum parts can transform a project from ordinary to extraordinary by enhancing performance and durability." This statement encapsulates the essence of choosing suitable aluminum components for any undertaking, whether it’s in aerospace, automotive, or consumer goods.

When considering Aluminum Parts for your project, several factors come into play, including alloy composition, extrusion methods, and surface treatment options. Understanding these elements ensures that the chosen components not only meet technical specifications but also align with the overall goals of your project. As innovation continues to drive the industry forward, knowing how to navigate the options available is essential for achieving the best results. By delving into this complete guide, you will be equipped with the knowledge necessary to make informed decisions about Aluminum Parts and their applications.

When selecting aluminum parts for a project, the first step is to clearly identify the specific requirements of your project. Consider factors such as the intended application, load-bearing capacity, and environmental conditions. For instance, if the parts will be used in a high-stress environment, you may need to choose aluminum alloys with higher tensile strength. Understanding the purpose of the aluminum components will guide you in making informed decisions, ensuring that they function adequately within the overall design.

Another important aspect to evaluate is the dimensions and tolerances required for your project. Accurate specifications are crucial for the seamless integration of aluminum parts with other components. Measurements such as thickness, length, and weight can significantly impact the effectiveness and durability of your products. Additionally, consider whether these parts require any surface treatments or coatings to enhance corrosion resistance or aesthetics, as such details will further define your project needs and affect the selection process.

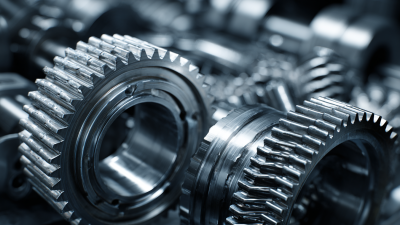

When selecting aluminum parts for your project, understanding the various types of aluminum alloys is crucial. Aluminum alloys are categorized into two main groups: wrought and cast. Wrought alloys, such as the 1000, 2000, and 6000 series, are known for their excellent workability and strength-to-weight ratio. They are commonly used in applications requiring high durability and corrosion resistance, making them ideal for structural components, automotive parts, and aerospace applications. On the other hand, cast alloys, typically identified by the 4xxx and 5xxx series, offer greater fluidity for casting processes and are convenient for producing complex shapes.

Tip: When choosing an aluminum alloy, consider the specific requirements of your project, including the environment it will be exposed to, the mechanical properties needed, and how the parts will be manufactured. This will guide you in selecting the right alloy to ensure optimal performance.

Another important factor in alloy selection is the heat treatment process. Some alloys can be heat-treated to improve their strength, while others may lose ductility and toughness. For instance, alloys in the 2000 and 7000 series benefit significantly from heat treatment, making them suitable for high-stress applications.

Tip: Always consult technical data sheets or industry resources to understand the heat treatment capabilities of a specific alloy. This knowledge can prevent costly mistakes and ensure your project meets the required performance standards.

When selecting aluminum components for your project, several critical factors need to be considered to ensure optimal performance and durability. The alloy type is a primary consideration, as different alloys exhibit varying strengths, corrosion resistance, and workability. For instance, according to the Aluminum Association, 6061 and 7075 alloys are frequently chosen for their high strength-to-weight ratios, making them ideal for structural applications. The choice of alloy can significantly impact the weight of the final product, which is essential in industries such as aerospace and automotive where weight reduction is crucial for efficiency.

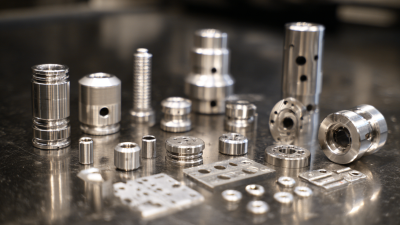

Another vital aspect to consider is the manufacturing process. Techniques such as extrusion, casting, and machining can affect the mechanical properties of the aluminum parts. Reports from the International Aluminum Institute indicate that extruded aluminum accounts for over 60% of the total aluminum usage in the construction sector due to its versatility and cost-effectiveness. The thickness, tolerances, and surface finish required for your components will also depend on the intended application, demanding precise specifications to meet industry standards.

Additionally, cost efficiency is a major factor when choosing aluminum components. A comprehensive study by the Aluminum Association highlights that while aluminum may have a higher initial cost compared to other materials, its lightweight and recyclability can lead to significant long-term savings. Therefore, it's essential to weigh not only the upfront costs but also the lifecycle benefits when determining the best aluminum parts for your project.

When selecting aluminum parts for your project, understanding the various manufacturing processes is crucial. The two primary methods commonly used in aluminum fabrication are extrusion and machining. According to a report by the Aluminum Association, aluminum extrusion allows for complex shapes while maintaining tight tolerances, which is essential for parts that demand precision. This process can also lead to faster production times and reduced waste, enhancing the overall sustainability of the manufacturing process.

Machining, on the other hand, is often chosen for its versatility and the ability to produce high-quantity orders with consistent quality. Industry research indicates that machining processes contribute to about 30% of all aluminum component manufacturing. This technique allows for greater detail and customization, catering to specific engineering requirements. It's important to evaluate these manufacturing options against your project specifications, such as volume, part complexity, and timeline, as the right choice can significantly impact both cost and performance in the final application.

Understanding the trade-offs associated with each process, including lead times and surface finish requirements, will help you make informed decisions. A comprehensive evaluation of the manufacturing process not only ensures that the aluminum parts meet the design intent but also aligns with the overall goals of your project, maximizing efficiency and quality outcomes.

When selecting aluminum parts for your project, ensuring quality and compliance is paramount. The first step in this process involves understanding the specific requirements of your application. This includes evaluating factors such as mechanical properties, corrosion resistance, and the environment in which the aluminum will be utilized. It’s crucial to select materials that meet applicable industry standards to ensure that the parts will not only perform as expected but also adhere to regulatory requirements.

Additionally, sourcing aluminum from reputable suppliers is essential for maintaining compliance and quality. Always request certificates of compliance or test reports to verify that the materials meet the required specifications. Implementing a robust quality control process during the procurement and manufacturing stages can help identify any potential issues early on. Regular audits of suppliers and their production methods can further guarantee that the aluminum parts will stand up to scrutiny and perform reliably throughout their intended usage.