Choosing the right Precision CNC Machining Center is crucial for any manufacturing business. According to industry expert Dr. Emily Carter, "Investing in the right equipment shapes the future of your production." Her words emphasize the importance of making informed choices.

When exploring options for Precision CNC Machining Centers, it’s essential to understand your specific needs. Each center offers unique features and capabilities. Factors like material compatibility, speed, and precision can vary significantly. It's easy to overlook these details when making a decision. Yet, considering them helps prevent costly mistakes.

Evaluating your production goals is vital. What works for one operation may not suit another. A common mistake is to rush this choice. Be cautious about falling for flashy advertisements. Instead, focus on tangible benefits and real-world performance. Choosing wisely leads to increased efficiency and profitability in the long run.

Precision CNC machining centers play a crucial role in manufacturing. They allow for high-speed and accurate production. According to a market analysis by ResearchAndMarkets, the global CNC machining market is expected to reach $100 billion by 2025. As businesses strive for efficiency, understanding these machines is vital.

When choosing a CNC machining center, consider several factors. The size of the workpiece is essential. Larger projects require bigger machines. Precision levels vary across models, influencing the final product quality. The tolerances for aerospace components, for example, can be as tight as ±0.001 inches. This highlights the need for high precision.

Operators also face challenges, such as maintenance costs and operational training. A report from the Technical University of Munich notes that about 20% of CNC machine downtime results from inadequate training. Reflecting on how to balance technology with skills development is essential. Investing in better-trained staff can reduce errors significantly, leading to improved outcomes.

Choosing the right precision CNC machining center involves several key factors. First, consider the size of your operations. Are you a small shop or a large manufacturing facility? The scale will affect the type of machine you need. Smaller companies may benefit from a compact model, while larger enterprises might require more robust equipment.

Next, think about the materials you will be machining. Different CNC machines excel in processing various materials. Some may handle metals better than plastics. Assess your typical workload. If you frequently switch between materials, look for a versatile center.

Don't overlook the software compatibility of the machining center. The control system should mesh well with your existing setup. Misalignments here can lead to costly errors. Finally, think about the support services that are available. A great machine becomes less valuable without proper technical assistance when issues arise. Consider these aspects carefully to make an informed decision.

| Factor | Description | Importance Level |

|---|---|---|

| Type of Material | Determines tool selection, speeds, and feeds that can be used. | High |

| Precision Requirements | Specifications for tolerances and surface finish. | Critical |

| Production Volume | Determines machine capacity and type of CNC center needed. | Moderate |

| Budget | Includes initial purchase, maintenance, and operation costs. | High |

| Software Compatibility | Integration with existing CAD and CAM software. | Moderate |

| After-Sales Support | Quality of customer service and technical support. | High |

When choosing a CNC machining center, precision and accuracy are critical. Studies show that precision impacts the overall quality of a project. For example, a report by the National Institute of Standards and Technology indicates that a variance of just 0.001 inches can lead to significant flaws in high-precision components. Understanding the specific needs of your project can guide you in selecting the right equipment.

Consider the tolerances required for your applications. If your project demands tight tolerances of ±0.0005 inches, then a high-end CNC machine with advanced capabilities is necessary. Some machines might not meet these standards, causing unexpected delays and additional costs. Pay attention to the features offered by different machining centers. Some may excel in speed but fall short in precision.

Evaluate the types of materials being used as well. Harder materials may require machines with unique setups or tooling. A common oversight is underestimating the complexity involved in machining demanding materials like titanium. Identifying potential problems upfront can help avoid costly errors. Remember, the right CNC machining center is not just about advanced technology; it's also about aligning those capabilities with your project’s specific precision requirements.

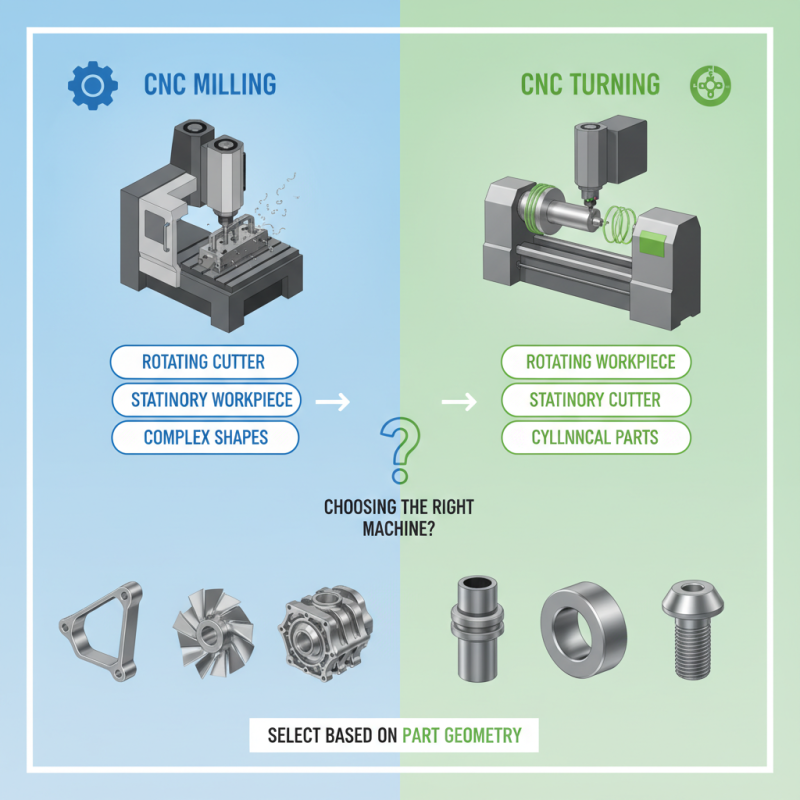

When choosing a precision CNC machining center, understanding the available technologies is essential. CNC machining encompasses various methods, each with unique capabilities. For example, milling and turning are common processes, yet they serve different purposes. Milling is great for creating complex shapes, while turning excels in producing cylindrical parts. This distinction is crucial for selecting the right machine.

Another aspect to consider is the material compatibility of each technology. Some machines handle metals better, while others are suited for plastics. Knowing your material can help narrow down the options. Additionally, the level of automation varies among different CNC centers. Fully automated machines can boost productivity but may require higher initial investment. Don’t overlook your budget constraints when assessing your needs.

Furthermore, the learning curve for each machine can be steep. Operators may need extensive training, which impacts your workflow efficiency. Investing in a sophisticated CNC machine is tempting, but consider whether your team can manage it. Reflecting on these factors will lead to a more informed decision. Ultimately, the right CNC machining center aligns with both your project requirements and operational capabilities.

When selecting a CNC machining center, assessing budget and cost-effectiveness is crucial. Industry reports indicate that precision machining can account for up to 30% of total manufacturing costs. It’s essential to determine your financial limits early on. High-quality machines often come with a premium. However, a cheaper option might lead to higher maintenance costs over time.

Consider the lifecycle cost of the CNC machine. This includes purchase price, operational costs, and maintenance expenses. Research by the International Society of Automation shows that up to 40% of overall costs can arise after purchase. So, prioritize not just initial cost but long-term savings.

**Tips:**

Evaluate the expected production volume. High output may justify a larger upfront investment due to more significant savings in per-part cost.

Beware of hidden costs. Things like software licenses and training sessions can add to the expense. Comparing different models can sometimes uncover significant discrepancies.

Do not overlook the machine's efficiency. A less expensive machine could cost you more in energy consumption. Always factor in how energy-efficient the model is. These considerations can make a notable difference in overall budget management.