In the rapidly evolving world of manufacturing, the CNC Machining Center has emerged as a pivotal technology, facilitating precision, efficiency, and flexibility in production processes. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 117.11 billion by 2026, growth fueled by the increasing demand for automation and the need for high-quality manufacturing solutions. As industries from aerospace to automotive seek to optimize their operations, selecting the right CNC Machining Center becomes critical to meeting both production targets and quality standards.

Choosing an ideal CNC Machining Center involves careful consideration of various factors, including the type of materials being processed, the required precision levels, and the complexity of the designs. A recent study by Statista highlights the growing adoption of CNC technologies among small to medium-sized enterprises, indicating a shift in the manufacturing landscape towards more sophisticated and versatile equipment. This guide serves as a comprehensive resource for decision-makers, offering insights and best practices to ensure their investment in a CNC Machining Center aligns with their operational goals and enhances their overall productivity.

CNC machining centers play a pivotal role in modern manufacturing, serving as the backbone of precision engineering in various industries. These advanced machines integrate computer numerical control technology with robust mechanical systems, allowing for the automated production of intricate parts with high accuracy. The ability to carry out multiple processes such as milling, drilling, and turning within a single setup reduces production time and minimizes the risk of errors, making CNC machining centers indispensable in today's fast-paced production environments.

Understanding CNC machining centers involves recognizing their importance in enhancing production efficiency and improving product quality. With their programmability, these centers can consistently replicate complex geometries, which is crucial for industries that demand high precision, such as aerospace, automotive, and medical manufacturing. Moreover, the flexibility of CNC machining centers enables manufacturers to quickly adapt to changing designs and production requirements, facilitating innovation and reducing lead times. As such, investing in the right CNC machining center is vital for businesses aiming to remain competitive in an increasingly automated and demanding marketplace.

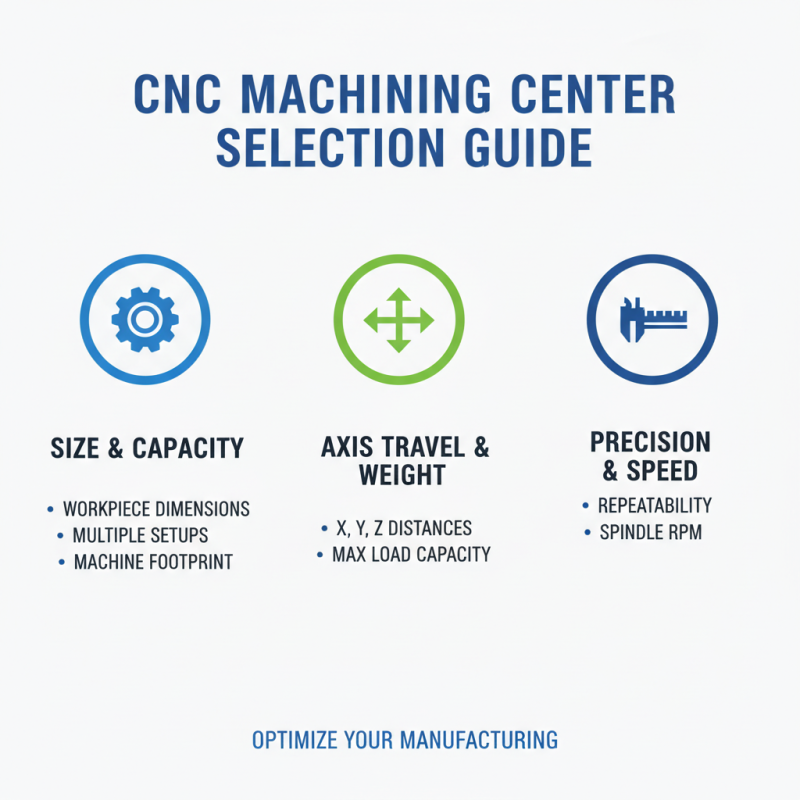

When selecting a CNC machining center, certain key features should be prioritized to ensure it meets your specific manufacturing needs. First and foremost, consider the size and capacity of the machining center. Depending on the scale of your operations, you may require a machine that can handle larger workpieces or accommodate multiple setups. Additionally, the travel distances of the axes, as well as the maximum weight the machine can support, are critical factors that influence both efficiency and performance.

Another vital aspect to evaluate is the type of control system utilized by the CNC machining center. A user-friendly interface with robust programming capabilities can significantly enhance productivity and reduce setup times. Compatibility with various software platforms is also essential, as it allows for greater flexibility in design alterations and tooling options. Furthermore, examine the machine's spindle speed and torque, as these attributes dictate the range of materials that can be effectively processed, ultimately affecting the quality of the finished product.

Lastly, consider the machine’s maintainability and support services available. Regular maintenance is crucial for long-term performance, so a machine with accessible parts and a clear service schedule can save costs and minimize downtime. Understanding the warranty and the availability of technical support will assist in making an informed decision that aligns with your operational goals. By focusing on these features, you can ensure that the CNC machining center you choose will enhance your production capabilities effectively.

CNC machining centers come in various types, each designed for specific applications within the manufacturing sector. The three most common types are vertical machining centers (VMCs), horizontal machining centers (HMCs), and five-axis machining centers. VMCs are prevalent due to their versatility and ease of use, making them suitable for smaller shops and a wide range of tasks, from simple milling to complex contouring. According to a report by the Association for Manufacturing Technology, VMCs accounted for nearly 47% of the CNC machine tool market in 2022, highlighting their widespread adoption.

In contrast, HMCs are favored for larger production runs and more expansive workpieces. Their horizontal spindle orientation allows for better chip removal and increased stability during operations, making them ideal for high-volume tasks. A study published by Techsci Research indicated that the global horizontal machining center market is projected to expand at a CAGR of 6.5% from 2023 to 2028, driven by advancements in precision engineering and the growing demand for automation in manufacturing.

Five-axis machining centers represent the cutting edge of CNC technology, enabling manufacturers to perform complex geometries in a single setup, which can drastically reduce production time and increase accuracy. They are particularly useful in industries such as aerospace and medical device manufacturing, where precision is critical. According to a recent report from Market Research Future, the five-axis CNC machining centers market is expected to grow significantly, with an anticipated CAGR of 8.2% over the next five years, underscoring their increasing importance in advanced manufacturing processes.

When evaluating CNC machining centers, it is crucial to focus on specifications and performance metrics that align with your production needs. Key specifications include the machine's axis configuration, spindle speed, and feed rate. For instance, machines with more axes provide increased versatility, allowing for complex geometries and detailed machining. Spindle speed is equally important; higher speeds can improve productivity by reducing machining time, while feed rates must be optimized to ensure a balance between efficiency and surface finish quality.

Performance metrics should not be overlooked; they can significantly influence operational efficiency and part accuracy. The machine's repeatability and precision ratings are essential indicators of how well it can perform over time. Look for details on rigidity and thermal stability, as these factors will affect performance during prolonged machining tasks. Additionally, consider the machine’s ability to handle different materials, as this can expand your production capabilities. Evaluate how user-friendly the CNC interface is, as this can impact the training time for operators and overall workflow efficiency. By carefully assessing these specifications and performance aspects, you can select a CNC machining center that best meets your manufacturing requirements.

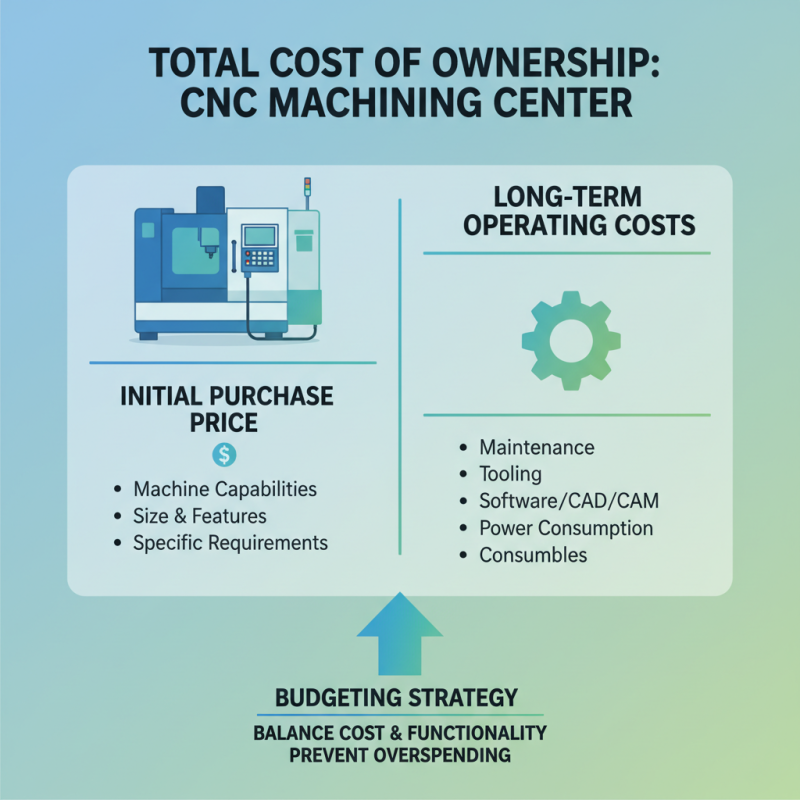

When budgeting for a CNC machining center, it's crucial to consider not only the initial purchase price but also the long-term operating costs. The upfront cost can vary significantly based on the machine's capabilities, size, and features. Therefore, it’s essential to assess your specific machining requirements to identify a machine that balances cost and functionality. For businesses, understanding the total cost of ownership—incorporating maintenance, tooling, and software expenses—can provide a clearer financial picture and help prevent overspending.

Additionally, potential buyers should explore financing options that may make acquiring a CNC machining center more manageable. Leasing, loans, or even vendor financing can be viable ways to spread costs over time. This approach allows companies to invest in technology without burdening their cash flow. Moreover, factoring in operational efficiency—such as energy usage and production speed—can lead to more informed decisions that contribute positively to the budget in the long run. By carefully evaluating these elements, organizations can choose a CNC machining center that meets their needs while staying within budget.