In the realm of precision manufacturing, the significance of advanced technology cannot be overstated. Among the myriad tools available to manufacturers, the CNC Machining Center stands out as an essential component for achieving exacting standards of accuracy and efficiency. These sophisticated machines leverage computer numerical control to execute complex machining operations with remarkable precision, making them indispensable in today’s competitive manufacturing landscape.

CNC Machining Centers enable manufacturers to meet diverse production needs, accommodating a range of materials and intricate designs. The versatility of these machines allows for high repeatability, minimizing human error and streamlining production processes. As industries increasingly demand high-quality components produced at faster rates, the role of CNC Machining Centers has evolved from a luxury to a necessity, ensuring that businesses remain agile and responsive to market demands.

Investing in a CNC Machining Center not only enhances operational efficiency but also contributes to maintaining quality control. With the capability to produce identical parts consistently, manufacturers can uphold rigorous standards and satisfy customer expectations. Therefore, the adoption of CNC Machining Centers is critical for any organization aiming to thrive in the precision manufacturing arena.

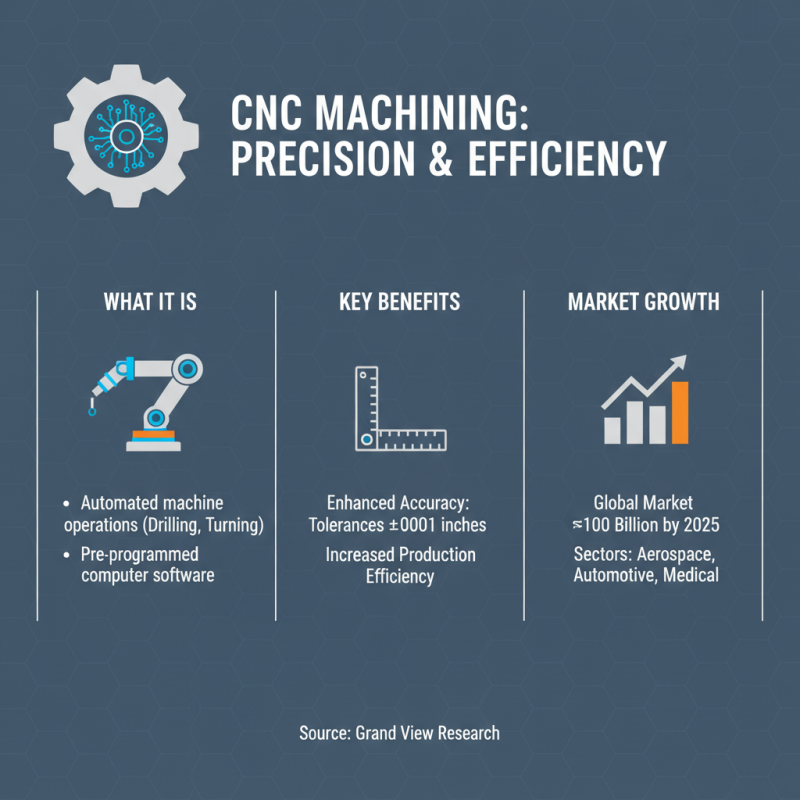

CNC (Computer Numerical Control) machining centers are integral to precision manufacturing, directly influencing production efficiency and product quality. Defined as sophisticated machines that operate based on pre-programmed computer software, CNC machining centers automate various machining processes, including drilling, milling, and turning. This automation enhances the accuracy of the operations, allowing manufacturers to achieve tolerances as tight as ±0.001 inches. According to a report by Grand View Research, the global CNC machining market is poised to reach approximately $100 billion by 2025, reflecting the growing demand for precision manufacturing across various sectors, including aerospace, automotive, and medical devices.

The functionality of CNC machining centers extends beyond mere automation; they provide manufacturers with the flexibility to produce complex geometries and intricate designs that would be challenging to achieve through traditional machining methods. With capabilities such as multi-axis machining, CNC centers can execute complex cuts and shapes in a single setup, thereby reducing production time and minimizing material waste. Industry data suggests that the adoption of CNC technology increases machining productivity by up to 30%, demonstrating its critical role in meeting the evolving precision manufacturing needs. As industries continue to innovate and demand higher quality standards, CNC machining centers will remain essential in ensuring that manufacturers can deliver consistent, high-precision products to the market.

CNC machining has revolutionized precision manufacturing by leveraging advanced technologies that ensure outstanding accuracy and efficiency. Key technologies behind CNC machining include computer-aided design (CAD) and computer-aided manufacturing (CAM) software, which allow engineers to create intricate designs and seamlessly translate them into machine code. This process facilitates the automated operation of machining tools, significantly reducing human error and enhancing the precision of the final products.

Another essential technology is the use of various CNC machining techniques, such as milling, turning, and electrical discharge machining (EDM). Each technique has its own strengths and applications, allowing manufacturers to select the most suitable method for their specific requirements. For instance, milling is ideal for creating complex shapes, while turning is best for generating cylindrical parts.

Tips: Always ensure that your CAD designs are optimized for manufacturability, taking into account the limitations and capabilities of the chosen CNC techniques. Regular maintenance of CNC machines is also crucial to maintain precision and extend the lifespan of the equipment. Investing time in training operators on the latest CNC technologies can significantly improve workflow efficiency and product quality.

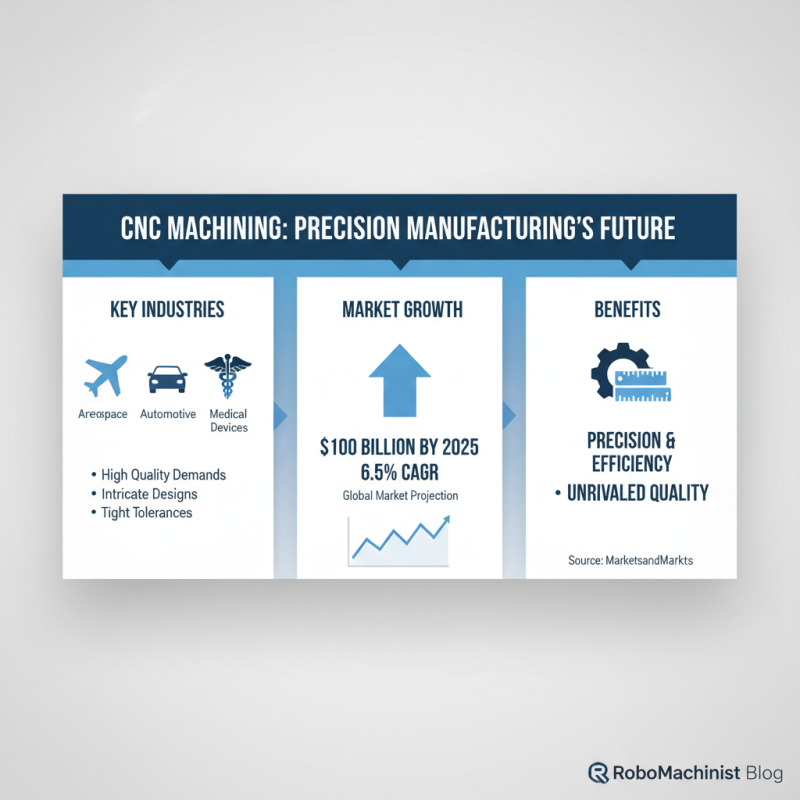

CNC machining centers have become indispensable tools in a variety of industries due to their ability to produce high-precision components swiftly and efficiently. In sectors such as aerospace, automotive, and medical device manufacturing, the demand for precision has never been higher. A report from MarketsandMarkets indicates that the global CNC machine market is expected to grow from $63 billion in 2021 to over $100 billion by 2026, driven primarily by advancements in automation and the increasing need for customized parts.

In the aerospace industry, where safety and precision are critical, CNC machining centers are employed to create complex components that often feature intricate geometries. According to the Aerospace Industries Association, the sector is projected to experience a compound annual growth rate (CAGR) of 4.5% through 2025, with the reliance on CNC machining technologies playing a significant role in meeting this growth. Additionally, medical device manufacturing has similarly benefited, as high-precision parts such as implants and surgical instruments are crucial for effective healthcare delivery. A report from Grand View Research states that the global medical device market is anticipated to reach $600 billion by 2024, with CNC machining being pivotal in producing safe and reliable products to meet regulatory standards.

Furthermore, industries such as electronics and energy are increasingly implementing CNC machining centers to enhance their production capabilities. Custom components for consumer electronics, including casings and brackets, require both precision and flexibility, attributes that CNC machines provide. The global electronics market is expected to grow significantly, estimated at over $5 trillion by 2025, showcasing the critical role CNC machining plays in not only meeting current demands but also driving innovation within these sectors.

CNC machining has become an indispensable tool in precision manufacturing, offering numerous benefits that cater to the ever-increasing quality demands of industries such as aerospace, automotive, and medical device production. According to a report by MarketsandMarkets, the global CNC machining market is projected to reach $100 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.5%. This growth is largely fueled by the precision and efficiency that CNC machining centers provide, enabling manufacturers to deliver intricate designs and tolerances within tight specifications.

One of the most significant advantages of CNC machining is its ability to produce highly complex parts with repeatable accuracy. Studies indicate that CNC machines can reduce production time by up to 75% compared to traditional machining methods. This efficiency not only lowers costs associated with labor and material wastage but also allows for quicker turnaround times, which is crucial in today’s fast-paced market. Furthermore, CNC machining minimizes human error, ensuring consistent quality in mass production, which is vital for sectors where even minor deviations can lead to catastrophic failures or substantial financial losses.

Additionally, CNC machining centers provide unparalleled versatility, capable of working with various materials, including metals, plastics, and composites. As per the latest data from Freedonia Group, demand for CNC-machined metal parts is expected to rise significantly, driven by advancements in machining technology and the growing need for lightweight materials in industries such as automotive and aerospace. This adaptability not only streamlines the manufacturing process but also supports innovation by allowing for rapid prototyping and customization in response to specific client needs.

The future of CNC machining technology is set to evolve dramatically, driven by advancements in artificial intelligence, automation, and material science. As manufacturers seek greater precision and efficiency, innovations such as machine learning algorithms will enhance machining processes, enabling real-time adjustments and reducing the risk of human error. These technologies not only optimize production speed but also improve the overall quality of the finished products.

Tips for manufacturers include investing in the latest CNC software that integrates AI capabilities, ensuring that teams are trained to utilize these advanced tools effectively. Furthermore, exploring additive manufacturing in conjunction with CNC machining can lead to innovative design possibilities, allowing for the creation of complex geometries that were previously unattainable. Staying attuned to these trends will not only keep businesses competitive but will also enhance their ability to meet increasingly stringent precision manufacturing demands.

Additionally, integrating IoT (Internet of Things) technology into CNC machines can provide real-time data analytics, allowing manufacturers to monitor performance continuously. This connectivity ensures that potential issues can be addressed proactively, thus minimizing downtime and maximizing productivity. Regularly evaluating and upgrading CNC equipment in line with technological advancements will be essential for maintaining a competitive edge in this rapidly evolving industry.

| Feature | Current Capabilities | Future Trends | Innovations |

|---|---|---|---|

| Accuracy | Up to ±0.005 mm | Sub-micron precision | Laser-assisted machining |

| Speed | Spatial feeds of 15 m/min | Automation leading to faster cycles | AI-controlled feeds |

| Materials | Metals, plastics, composites | Expanded material compatibility | 3D printable materials |

| Software Integration | Basic CAM systems | Full integration with IoT | Cloud-based simulation tools |

| Maintenance | Scheduled maintenance | Predictive maintenance | AI diagnostics |