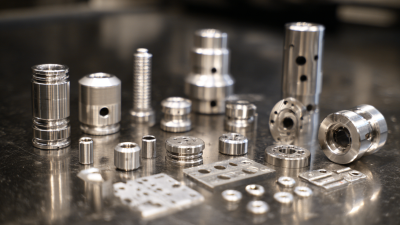

CNC machined aluminum parts have become a cornerstone in various manufacturing sectors, ranging from aerospace to automotive and consumer electronics. According to a report by Grand View Research, the global CNC machining market was valued at approximately $63.89 billion in 2020 and is projected to experience a compound annual growth rate (CAGR) of 6.6% from 2021 to 2028. The rising demand for precision components, particularly those made from aluminum due to its lightweight and corrosion-resistant properties, has further accelerated this growth.

As industries evolve, the need for high-quality, precision-engineered parts has never been more critical. CNC machined aluminum parts offer superior strength-to-weight ratios and are highly customizable, making them ideal for intricate designs and functionalities. The versatility of aluminum, coupled with the rapid advancements in CNC technology, empowers manufacturers to produce complex shapes and dimensions that meet the rigorous standards of modern applications. However, with a plethora of options available in the market, selecting the right CNC machined aluminum parts can be a daunting task, necessitating a strategic approach to ensure optimal performance and value for your projects.

When selecting CNC machined aluminum alloys for your projects, several key factors need consideration to ensure optimal performance and efficient fabrication. One of the primary considerations is the alloy type. Aluminum alloys can be categorized into various series, with each series offering distinct properties, such as strength, corrosion resistance, and workability. For instance, the 6000 series alloys are popular for their excellent corrosion resistance and weldability, making them a suitable choice for a wide range of applications.

Another important factor is the thickness and tolerances of the parts. Depending on your project requirements, you might need specific dimensions that can affect the selection of the alloy. Meticulous attention to tolerances is crucial, especially in precision applications. It is advisable to consult with your CNC machining provider to specify these dimensions clearly and ensure that the selected alloy can meet the necessary standards.

Tip: Always consider the end-use of the aluminum parts. If the components will be exposed to harsh environments, opting for alloys with enhanced corrosion resistance will be advantageous. Additionally, evaluating the potential heat treatment processes available for the selected alloy can significantly affect the mechanical properties of the end product, further ensuring that the parts perform as intended in their operational context.

When selecting CNC machined aluminum parts for your projects, understanding tolerances is crucial for ensuring the precision and overall quality of the final product. Tolerances refer to the permissible limits of variation in a physical dimension, which can significantly affect both the fit and functionality of the components being produced. In CNC machining, tighter tolerances generally require more sophisticated machinery and longer machining times, which can impact both cost and lead time.

The impact of tolerances on quality cannot be overstated. If the tolerances specified for parts are too loose, it could lead to assemblies that do not function properly or that may wear prematurely. Conversely, overly tight tolerances may lead to unnecessary complexity in production and increased costs.

Therefore, it is essential to strike a balance by determining the required tolerances based on the application of the part, ensuring that both performance and manufacturability are optimized. Understanding how different tolerances affect the machining process will empower you to make informed decisions, ultimately leading to a successful project outcome.

When selecting CNC machined aluminum parts, one crucial aspect to consider is the surface finish. The surface finish not only affects the aesthetics of the parts but also plays a significant role in their performance and longevity. Different finishes can enhance corrosion resistance, reduce friction, and improve thermal conductivity, all of which are essential for the specific application of the parts. Anodizing, for example, is a popular choice as it adds a protective layer that improves durability while also allowing for a variety of color options.

When deciding on surface finishes, consider the intended use of the aluminum parts in your projects. If they will be exposed to harsh environmental conditions, opting for finishes that enhance protection against corrosion is vital. For aesthetic purposes, polished or brushed finishes can elevate the overall appearance of the parts, making them suitable for visible applications. Additionally, ensure to communicate any specific requirements for the finish with your CNC machinist, as this will impact the final production quality.

Tip 1: Evaluate the functional requirements of your project before choosing the surface finish to ensure it meets both aesthetic and practical needs. Tip 2: Consult with professionals about surface finishes that may optimize properties like wear resistance or thermal management based on your project's requirements. Making informed decisions on finishes can significantly affect the performance and lifespan of your CNC machined aluminum parts.

| Tip | Description | Surface Finish Type | Benefits |

|---|---|---|---|

| 1. Define Your Requirements | Understand the specifications and tolerances needed for your project. | N/A | Ensures the part fits perfectly into the design. |

| 2. Select the Right Alloy | Choose an aluminum alloy that matches your application requirements. | 6061, 7075 | Improved strength and corrosion resistance. |

| 3. Precision Machining | Ensure the manufacturer uses CNC machining for high precision. | N/A | Enhances design accuracy and repeatability. |

| 4. Understand Surface Finishes | Learn about different surface finishes and their purposes. | Anodizing, Powder Coating | Improves aesthetics and durability. |

| 5. Evaluate Cost | Consider the overall cost, including materials and finishing. | N/A | Ensures the project stays within budget. |

| 6. Check for Certifications | Ensure the manufacturer complies with industry standards. | ISO, AS9100 | Guarantees quality and reliability. |

| 7. Sample Testing | Request samples to test fit and finish before bulk orders. | N/A | Validates manufacturing capabilities. |

| 8. Lead Times | Discuss timelines for production and delivery. | N/A | Helps in project scheduling. |

| 9. Post-Processing Options | Explore finishing options available post-machining. | Polishing, Bead Blasting | Enhances appearance and performance. |

| 10. Communication | Maintain open communication to clarify needs and updates. | N/A | Ensures project success and satisfaction. |

When selecting CNC machined aluminum parts for your projects, evaluating supplier capabilities and certifications is critical to ensuring quality and reliability. According to a recent industry report by the Manufacturers Alliance for Productivity and Innovation, nearly 70% of manufacturing defects stem from inadequate supplier selection processes. Therefore, understanding a supplier's certifications, such as ISO 9001, can provide reassurance regarding their commitment to quality management systems and continuous improvement. These certifications reflect the supplier's ability to produce components that meet the stringent requirements set by industry standards.

Furthermore, assessing supplier capabilities goes beyond certifications; it involves analyzing their technical expertise and production capacity. A study by TechNavio revealed that more than 80% of successful projects are linked to suppliers who employ advanced machining technologies and skilled personnel. Investigating a supplier's machining equipment and processes, such as the adoption of CNC technology with multi-axis capabilities, can indicate their potential to handle complex designs and deliver precise results. Additionally, looking into their past performance metrics can further substantiate their reliability, allowing for more informed decision-making when choosing the right supplier for your CNC machined aluminum parts.

When considering the cost-effectiveness of CNC machined aluminum parts for your projects, it's essential to analyze both the material's affordability and the machining processes involved. Aluminum is favored in various industries due to its lightweight characteristics and high strength-to-weight ratio, which can significantly reduce overall project costs. Moreover, CNC machining allows for precision and high production rates, translating to lower labor costs over time.

To ensure you are making the most economically sound choices for your CNC machined aluminum components, here are some tips. First, evaluate the complexity of your design. Simpler designs often require less machining time and can reduce costs. Second, consider the size of your order; bulk purchasing may lead to discounts because of reduced setup and production times. Additionally, collaborating with a trusted CNC machining service can enhance communication and allow for adjustments without incurring significant expenses.

It's also critical to assess the quality of aluminum you require. While some projects might benefit from high-grade aluminum alloys, opting for a more standard type can yield significant savings without compromising functionality. In the long run, thorough planning and informed decisions can maximize both efficiency and budget, making CNC machined aluminum an ideal choice for many manufacturing projects.