Metal lathe parts are crucial in various industries, providing precision and efficiency in machining operations. According to a recent report by the International Association of Machinists, the global demand for metal lathe parts is projected to grow by 5.2% annually. This growth emphasizes the importance of understanding how metal lathe components function together.

Industry expert John Smith, a mechanical engineer with over 20 years of experience, states, "Quality metal lathe parts are the backbone of any successful machining project." His insight highlights the significance of these components in achieving high-quality finishes and precise measurements. Components like the spindle, tailstock, and carriage each play a vital role in the lathe's operation.

Despite advancements, challenges persist in manufacturing metal lathe parts. Many producers face issues related to material selection and production costs. Addressing these challenges requires continuous innovation. Understanding the intricacies of metal lathe parts is essential for professionals looking to enhance their machining practices. The industry must remain agile to adapt to evolving demands.

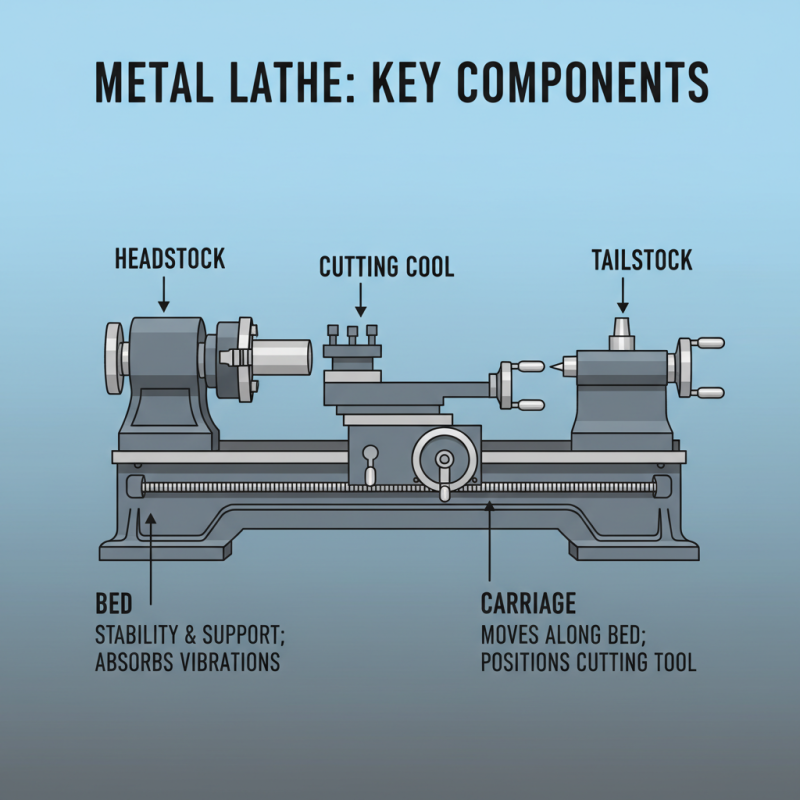

Metal lathe parts are essential components for precision machining. A metal lathe, primarily used for shaping metal, contains several key parts. These components include the bed, headstock, tailstock, carriage, and tool post. Each part plays a vital role in the lathe's operation, impacting accuracy and efficiency.

The bed forms the machine's foundation, providing support for all other parts. It needs to be both rigid and stable. Data from the American Machine Tool Distributors’ Association (AMTDA) indicates that a robust bed can improve the machine's performance by up to 30%. The headstock houses the main motor and spindle, where workpieces are mounted. It is crucial for the lathe's rotational speed, often requiring precise adjustments. The tailstock supports long workpieces during machining processes, ensuring stability.

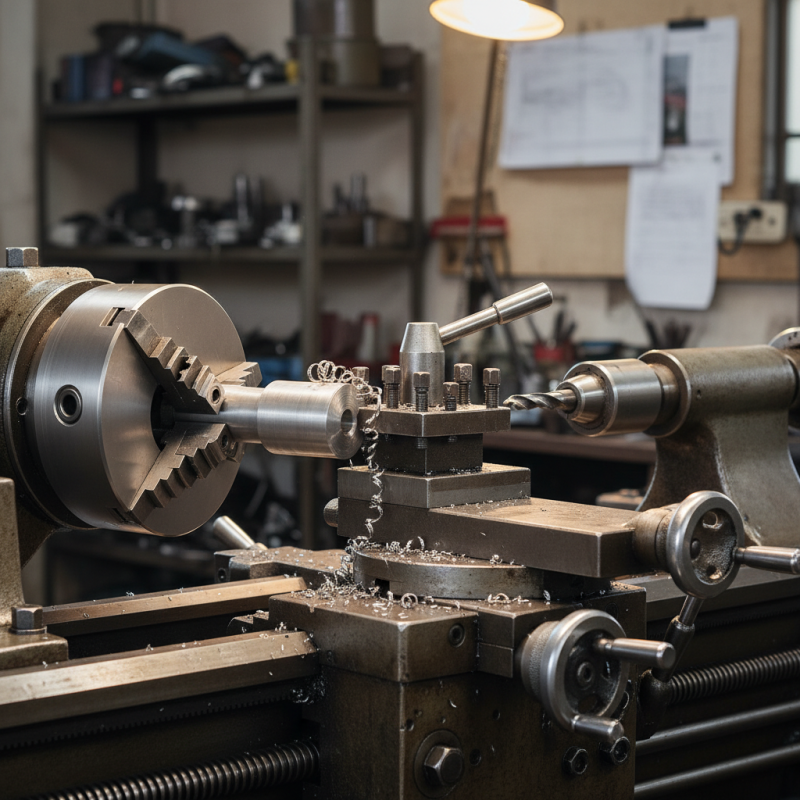

Moreover, the carriage holds the cutting tool and moves it along the workpiece. Interestingly, studies show that improper adjustments can lead to tool wear and reduced accuracy. This highlights the necessity for skilled operators to understand the mechanics behind these parts. Each component has its limitations, and recognizing them is essential for maximizing productivity. Issues like vibration or misalignment can hinder performance, requiring constant monitoring and adjustments.

A metal lathe is a sophisticated machine tool. It transforms metal into desired shapes. Understanding its main components is essential for efficient use.

The bed is the lathe's foundation, providing support and stability. It houses guides and ways for the carriage. Precision in these components is crucial. A report from the Manufacturing Technology Association stated that lathe bed alignment can impact machining accuracy by up to 30%. This highlights the importance of maintaining a sturdy bed.

The headstock is another vital part. It contains the spindle, allowing the workpiece to rotate. The spindle’s quality affects speed and torque. Poor spindle performance may lead to inefficiencies. This could slow production down or compromise project quality. The tailstock supports workpieces during machining. However, misalignment issues can occur, affecting overall precision. Regular checks can prevent mistakes. It’s important to reflect on these components when working with a lathe.

A metal lathe consists of several key parts, each performing a unique function. The bed provides stability and support for the entire machine. It absorbs vibrations and helps maintain accuracy during machining. The carriage moves along the bed, allowing the cutting tool to be positioned easily. This movement is vital for achieving the correct dimensions of the workpiece.

The spindle holds the workpiece in place and rotates it at high speeds. Its precision is crucial in producing parts with tight tolerances. The tailstock supports the other end of the workpiece and can hold additional tools for operations like drilling. Each part must be well-aligned to work effectively; misalignment can lead to errors.

As users interact with a metal lathe, they sometimes overlook minor adjustments. These small tweaks can significantly affect the final product's quality. Inexperience can lead to over-tightening components, causing damage. Regular maintenance is essential to prevent wear and tear, improving performance over time. Ensuring that all parts work harmoniously is a challenge but critical for success in machining.

Metal lathe parts are crafted from various materials, each chosen for specific properties. Common materials include steel, aluminum, and brass. Steel is often used for its strength and durability. It's suitable for high-stress applications. Aluminum is lightweight and easier to machine. It's preferred for parts that require tight tolerances. Brass is known for its corrosion resistance and good machinability.

When selecting materials, consider the part's application. Each metal has its benefits and drawbacks. Steel can withstand high temperatures, but it can be heavy. Aluminum may not offer the same strength, but it's perfect for intricate designs.

Tips: Always assess the manufacturing process. Different materials respond uniquely to machining methods. Experimenting with various combinations can lead to unexpected results. Don't hesitate to make adjustments based on what you observe. Through reflection, you can refine your approach and create better parts.

Metal lathe parts play a crucial role in various industries. These components are vital for shaping, cutting, and finishing metal pieces. In manufacturing, precision is key. Metal lathe parts enable this precision, allowing for the creation of complex shapes with high accuracy.

Applications are seen in automotive, aerospace, and machinery sectors. For instance, in the automotive industry, parts like shafts and gears are produced. These components directly affect the performance of vehicles.

However, the quality of these parts can vary. Not all lathe parts meet industry standards, leading to potential failures. The importance of metal lathe parts cannot be underestimated. They contribute significantly to production efficiency.

Yet, businesses must invest time in selecting the right parts. Doing so ensures smoother operations and better end products. Reflection on the procurement process is essential for sustained success.