In today's competitive manufacturing landscape, optimizing production processes is essential for businesses aiming to enhance efficiency and reduce costs. According to a recent industry report by Smithers Pira, the global CNC machining market is projected to reach $100 billion by 2025, with a significant portion attributed to CNC aluminum parts due to their lightweight properties and excellent machinability. Custom CNC aluminum parts, in particular, can lead to tailored solutions that meet specific design and performance requirements, ultimately contributing to a decrease in lead time and waste. As organizations continue to embrace automation and advanced manufacturing techniques, integrating custom CNC aluminum parts into their production workflows will be a pivotal strategy in maximizing productivity while maintaining high standards of quality and precision. This article will explore effective tips and strategies for optimizing your production with custom CNC aluminum components.

Custom CNC aluminum parts are revolutionizing production processes across various industries, significantly enhancing efficiency and reducing costs. According to a report by Deloitte, companies that implement advanced manufacturing technologies, including custom CNC machining, can increase production efficiency by up to 30%. This improvement stems from the ability to produce highly precise components that fit specifications perfectly, minimizing the need for extensive rework and waste.

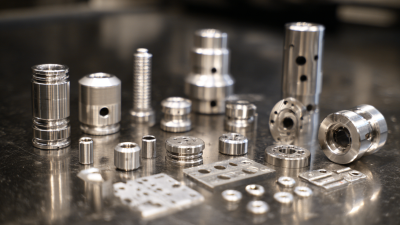

One key benefit of using custom CNC aluminum parts is the agility they provide in product development. Businesses can quickly prototype designs and make necessary adjustments without the long lead times typically associated with traditional manufacturing processes. Additionally, the lightweight nature of aluminum contributes to lower shipping costs and improved fuel efficiency in logistics, further streamlining production.

Tips: When choosing a supplier for custom CNC aluminum parts, ensure they possess ISO certification, as this often indicates adherence to high-quality manufacturing practices. Furthermore, consider investing in CNC parts that allow for modular designs. This enables easier scalability and customization in future production runs, allowing your business to adapt swiftly to market demands.

In recent years, CNC machining has become a significant contributor to the production efficiency of various industries, particularly in aluminum part manufacturing. Key statistics reveal that the global CNC machining market is projected to grow from $71 billion in 2021 to over $100 billion by 2026, emphasizing a strong demand for precision-engineered components. Moreover, employing custom CNC aluminum parts can reduce production costs by up to 30%, highlighting how tailored solutions can lead to both financial and operational efficiency.

Aluminum parts are favored in numerous applications due to their lightweight, corrosion-resistant, and versatile nature. The average cost of producing CNC aluminum parts can vary, but recent trends show that high-volume production can decrease costs significantly, making it an attractive option for manufacturers. By leveraging advanced CNC techniques and automation, companies are not only lowering their manufacturing expenses but also ensuring higher accuracy and shorter lead times in their production processes, ultimately enhancing their competitive edge in the market.

This chart presents the average production costs of custom CNC aluminum parts across various industries. The data highlights how costs can fluctuate depending on the complexity of parts and the volume of production.

The effective implementation of custom CNC aluminum parts can significantly enhance production efficiency, as demonstrated in several successful case studies. In one instance, a major automotive manufacturer incorporated custom machined components into their assembly line, replacing standard parts that were causing bottlenecks. The bespoke aluminum parts were designed to fit perfectly into existing systems, resulting in a 25% reduction in assembly time and a notable increase in overall production speed.

Another impressive example comes from the aerospace industry, where a company faced challenges with weight restrictions and component durability. By utilizing tailored CNC aluminum parts, they were able to produce lightweight yet robust components that not only met regulatory standards but also improved the performance of their aircraft. The ability to customize these parts allowed for innovative designs that pushed the limits of traditional manufacturing approaches, ensuring that the final products were both efficient and compliant with industry regulations. These case studies highlight the transformative power of custom CNC parts in optimizing production processes across various sectors.

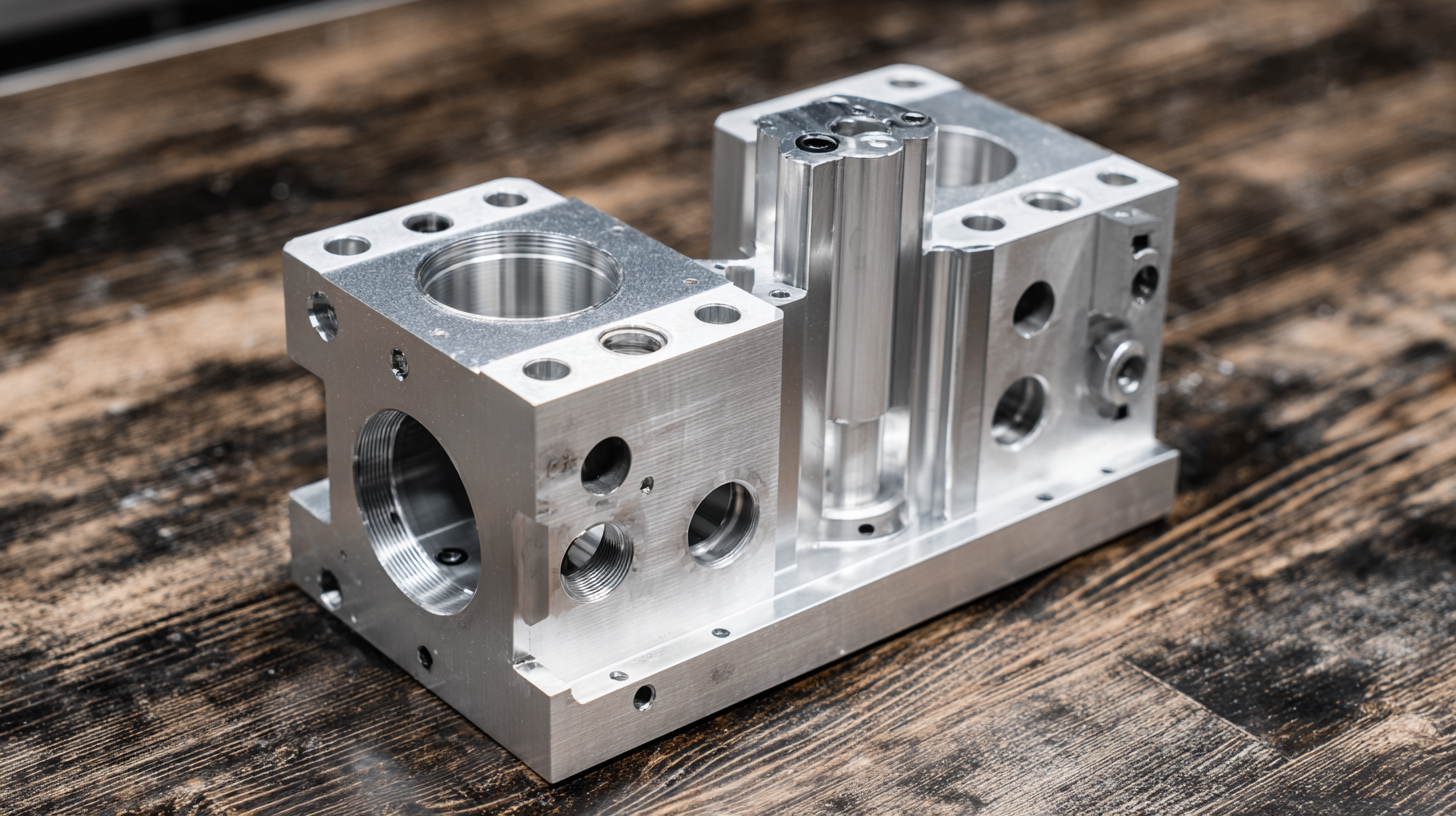

In the realm of manufacturing, the choice between standard and custom CNC aluminum parts is critical for optimizing production efficiency. According to a recent report by the Manufacturing Technology Association, companies that utilize custom CNC parts can reduce production times by up to 30%, thanks to tailored designs that fit specific operational needs. This adaptability not only streamlines workflows but also minimizes the need for additional modifications during assembly, a significant advantage over off-the-shelf solutions.

Moreover, the cost-effectiveness of custom parts becomes more apparent when considering long-term production runs. A study by the National Association of Manufacturers revealed that businesses using custom components often experience up to a 20% reduction in material waste, contributing to both lower costs and a smaller environmental footprint. This is in stark contrast to standard parts, which may necessitate adjustments or added hardware, ultimately inflating overall project expenses. In an era where precision and sustainability are paramount, custom CNC aluminum parts clearly stand out as a strategic choice for optimizing production and enhancing operational efficiency.

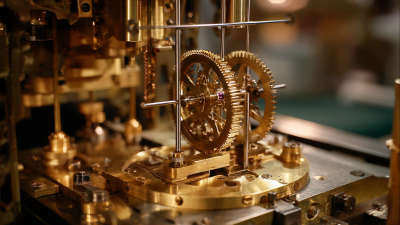

The future of CNC technology is marked by a wave of innovations that are reshaping the manufacturing landscape. Advances such as artificial intelligence and machine learning are increasingly being integrated into CNC machines, enabling real-time data analysis and process optimization. This allows manufacturers to predict failures before they occur, minimizing downtime and enhancing production efficiency. Moreover, smart factories equipped with IoT connectivity can monitor machine performance remotely, ensuring that operations are constantly fine-tuned for optimal output.

Another pivotal trend is the rise of additive-subtractive manufacturing, where CNC machining is paired with 3D printing techniques. This hybrid approach offers remarkable flexibility in producing complex components that were previously difficult or impossible to create. By leveraging the strengths of both technologies, manufacturers can achieve higher precision and reduce material waste. As these innovations continue to evolve, companies that embrace them will not only streamline their production processes but also gain a competitive edge in the fast-paced world of manufacturing.