Precision metal parts play a crucial role in modern manufacturing. They are vital for diverse industries such as aerospace, automotive, and electronics. The demand for these components continues to rise, driven by technological advancements.

These parts offer remarkable benefits, including improved durability and precision. Engineers rely on them for high-performance applications. For example, in aerospace, precision metal parts ensure safety and reliability. Yet, challenges remain in achieving the exact specifications needed. The process can be intricate and requires constant monitoring.

Incorporating precision metal parts can lead to significant cost savings. They enhance the efficiency of production lines and reduce waste. However, manufacturers must continuously assess quality control measures. This balance is essential for progress. Embracing innovation in this field is not without its challenges. It demands a commitment to excellence and a willingness to adapt.

Precision metal parts play a crucial role in various manufacturing sectors. They are known for their high accuracy and durability. A well-made part can fit perfectly into complex machinery. This is essential for operational efficiency. These parts often undergo extensive quality checks during production. However, achieving the desired level of precision can sometimes be challenging. Tolerances might not always meet expectations, leading to potential errors.

One of the key characteristics of precision metal parts is their ability to withstand harsh environments. Many applications involve extreme temperatures or corrosive substances. The materials used must be resilient. For instance, metals like stainless steel and titanium are popular choices. They provide strength without added weight. Sometimes, though, the selection process reveals unexpected limitations. Some metals may not perform well under specific conditions. This requires careful assessment during design stages.

Another notable trait is the versatility in manufacturing processes. Techniques such as CNC machining and 3D printing offer flexibility. These processes can create intricate designs with minimal waste. Yet, they also raise questions about reliability and scalability. Can every project benefit from precision engineering? Certain projects may still rely on traditional methods. In the pursuit of perfection, manufacturers must remain open to reflection and adaptation.

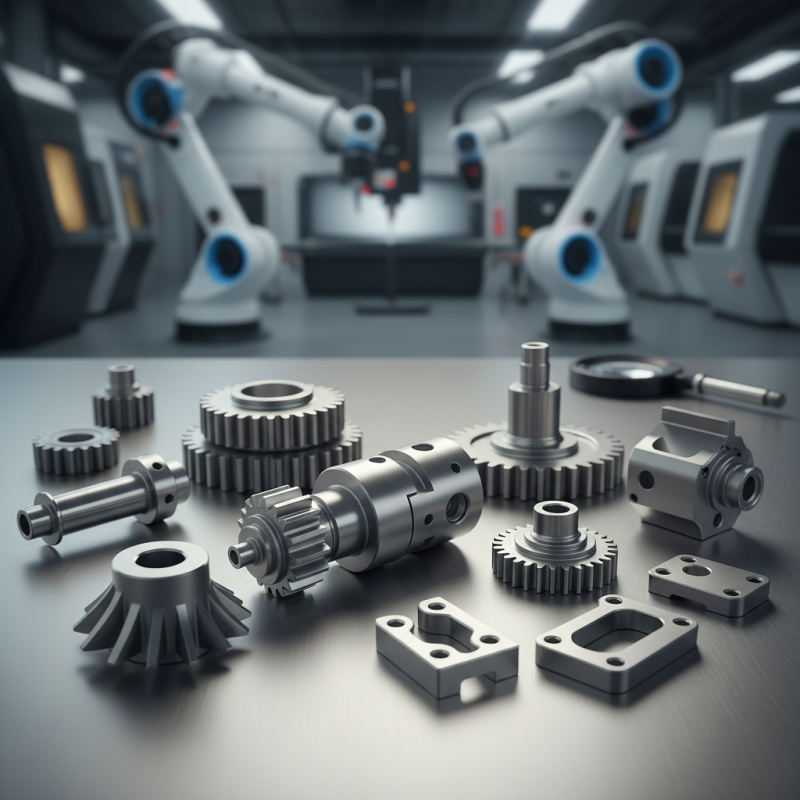

Precision metal parts have diverse applications across various industries. These components enhance functionality and efficiency. The choice of materials is crucial to achieve desired precision and durability. Common materials include aluminum, stainless steel, and titanium. Each material has unique properties that cater to specific needs.

Aluminum is lightweight and resistant to corrosion. It's often used in aerospace and automotive applications. Stainless steel offers excellent strength and resistance to rust. It's ideal for medical devices and food processing equipment. Titanium is known for its strength-to-weight ratio and is utilized in high-performance environments.

Choosing the right material is not always straightforward. Some materials may not meet all the desired criteria. Testing and evaluations are vital to ensure performance. These imperfections in material selection can lead to changes in design or production processes. Continual refinement is necessary to optimize precision part production.

This chart illustrates the distribution of various industry applications for precision metal parts. The aerospace sector leads with 35%, followed by automotive at 30%. Other sectors, including marine, medical, and electronics, contribute to the remaining percentages, highlighting the importance and versatility of precision metal components across multiple industries.

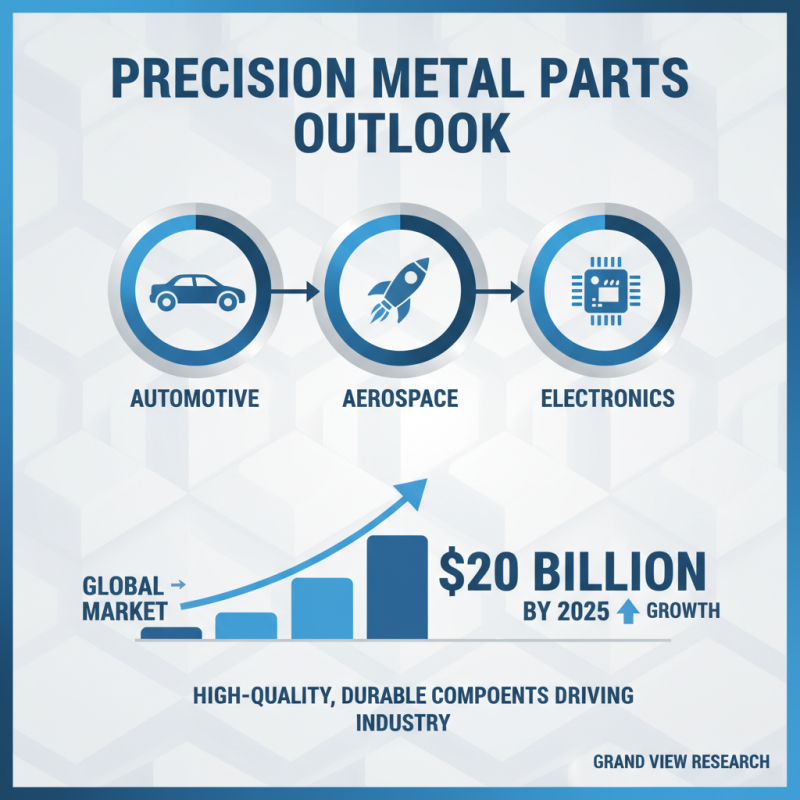

Precision metal parts are crucial in numerous industries. Automotive, aerospace, and electronics sectors heavily depend on these components. According to a recent report by Grand View Research, the global precision metal stamping market is expected to reach $20 billion by 2025. This growth highlights the rising demand for high-quality, durable parts.

In the automotive sector, precision metal parts improve vehicle performance and safety. These parts need to fit precisely to ensure proper functioning. A slight deviation can lead to significant issues. The aerospace industry also requires these components for aircraft engines and frames. A report from the Aerospace Industries Association mentions that precision manufacturing reduces weight, enhancing fuel efficiency and safety.

The electronics industry relies on precision metal parts for circuit boards and connectors. With rapid technological advancements, the need for miniaturization increases. A study from the Institute of Electrical and Electronics Engineers indicates that precision components help create smaller, more efficient devices. However, manufacturers face challenges in maintaining tolerances during mass production. It's crucial to balance quality and cost, ensuring that precision does not sacrifice affordability. This ongoing struggle requires attention and innovation.

Precision metal parts play a crucial role in many industries. They offer numerous benefits that can enhance production efficiency. A Market Report from Grand View Research states that the precision metal parts market is expected to reach $600 billion by 2025. This growth reflects the increasing demand for precision in manufacturing processes. Companies benefit from reduced waste and increased reliability when using these parts.

Utilizing precision metal parts can lead to better product performance. A precise fit can minimize the chances of failure. This is particularly important in sectors like aerospace and automotive. According to a report by Research and Markets, the aerospace segment accounts for over 25% of the total market. With such a significant portion relying on precision, the impact on safety and function is substantial. Yet, there are challenges. High manufacturing costs and complex processes can deter some companies from adoption.

Flexibility is another vital advantage. Manufacturers can tailor parts to specific requirements. This customization often results in optimized operations. However, the supply chain can be a hurdle. Sometimes delays occur that affect production timelines. This inconsistency can lead to greater inefficiencies and necessitates strategic planning. Reflecting on these aspects is crucial for any business aiming for precision metal parts.

The future of precision metal parts technology is bright and complex. Innovations are emerging rapidly across various industries. Advanced manufacturing techniques, such as additive manufacturing and CNC machining, enhance the precision of metal parts. These methods reduce waste and improve efficiency. They allow for intricate designs that were previously impossible.

Another trend is the integration of smart technologies. Sensors and IoT devices are becoming commonplace in metal parts. This integration enables real-time monitoring of performance. However, it also presents challenges. Companies must ensure data security and manage the complexity of these systems. The demand for lightweight materials is increasing too. Industries like aerospace and automotive are pushing for materials that maintain strength while reducing weight.

Despite these advancements, not all developments are seamless. High costs can be a barrier for small manufacturers. There can be a learning curve associated with new technologies. The need for skilled workers is ever-present. Balancing innovation with practical realizations remains a challenge. These evolving trends highlight both opportunities and obstacles ahead in precision metal parts applications.

| Application | Benefits | Material Used | Future Trends |

|---|---|---|---|

| Aerospace Components | Lightweight, durability, high strength | Aluminum alloys, Titanium | Increased automation and additive manufacturing |

| Medical Devices | Precision, biocompatibility, strength | Stainless steel, Plastic composites | Smart technologies and miniaturization |

| Automotive Parts | Efficiency, reduced weight, enhanced performance | Aluminum, High-strength steel | Electrification and sustainable materials |

| Electronics | Compactness, thermal conductivity | Copper, Aluminum | Integration of IoT and AI technologies |