In the rapidly evolving landscape of modern manufacturing, Precision Metal Parts have emerged as a cornerstone for success across various industries. According to a report by Grand View Research, the global precision metal parts market is expected to reach USD 148.1 billion by 2025, driven by increasing demand for high-quality components that meet stringent performance standards. These parts are essential in applications ranging from aerospace to automotive and electronics, where even the slightest deviation can lead to significant functional failures. Furthermore, as manufacturers adopt advanced technologies like additive manufacturing and CNC machining, the role of Precision Metal Parts becomes even more critical, enabling the production of intricate designs with improved efficiency and reduced waste. By investing in precision engineering, companies can not only enhance product quality but also achieve a competitive edge in a market where precision is paramount.

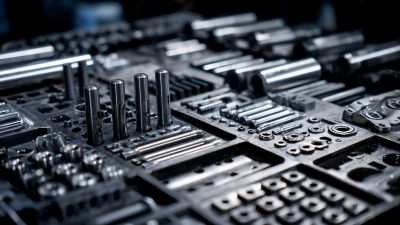

Precision metal parts play a critical role in streamlining manufacturing processes across various industries. These components are engineered to exact specifications, allowing manufacturers to achieve superior fitting and function in their products. By using precision metal parts, companies can minimize discrepancies in assembly, reduce wear and tear on machinery, and enhance overall product durability. This level of accuracy not only speeds up production times but also ensures that the final products meet the stringent quality standards set by both industry regulations and consumer expectations.

Moreover, the integration of precision metal parts into manufacturing workflows optimizes efficiency and reduces waste. Instead of relying on cumbersome trial-and-error methods, manufacturers can leverage advanced technology and precise measurements to ensure that every part is crafted to perfection. This precision enables seamless integration into larger systems, facilitating easier assembly and improving operational productivity. As industries continue to push for innovation and cost-effectiveness, the reliance on precision metal parts becomes increasingly vital for any manufacturing operation aiming for success in today’s competitive landscape.

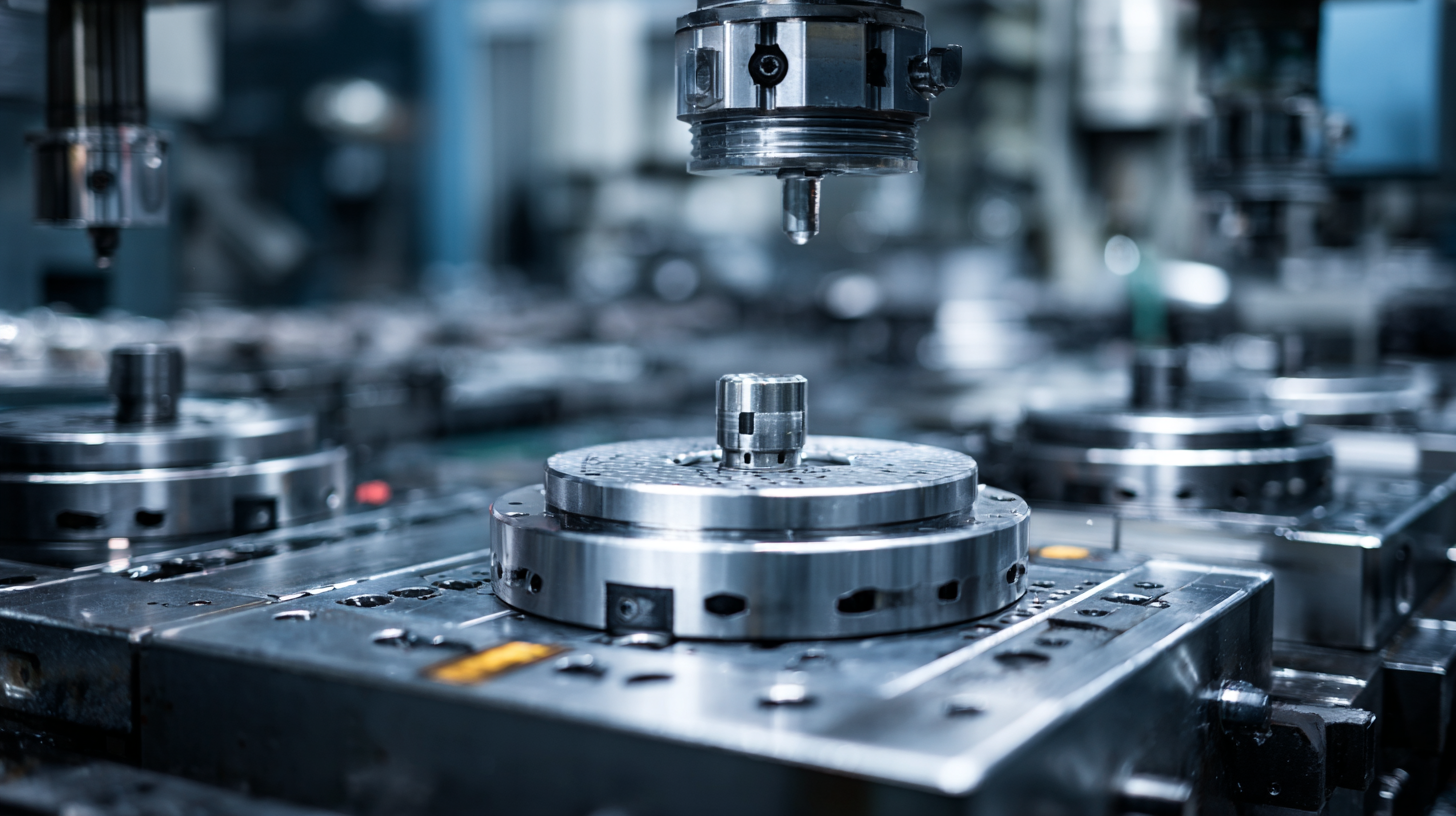

Precision metal parts play a crucial role in modern manufacturing, particularly in enhancing product quality through precision engineering. The integration of advanced technologies, such as computer vision and machine learning, into manufacturing processes has transformed productivity across various industries. According to a report by a leading industry research firm, companies that have adopted smart manufacturing technologies have seen productivity increases of up to 30%. This demonstrates how precise engineering can streamline operations and minimize errors.

Manufacturing industries face the constant challenge of producing high-quality, faultless products within tight timelines. A multidisciplinary approach is essential to overcome these hurdles. For instance, implementing control systems that leverage real-time data analysis can significantly enhance process accuracy. Research indicates that manufacturers employing these technologies have reduced defect rates by nearly 50%, highlighting the importance of precision metal parts in achieving overall operational excellence. The commitment to precision not only improves product reliability but also positions companies to meet the evolving demands of consumers in a competitive market.

This bar chart illustrates the correlation between precision metal parts and product quality across various manufacturing sectors. Higher precision generally leads to higher quality outputs, essential for modern competitive manufacturing.

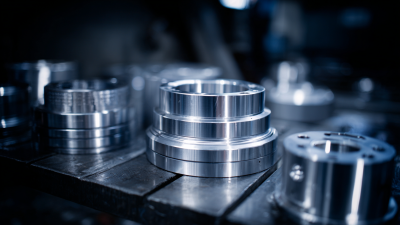

Precision metal parts play a pivotal role in contemporary manufacturing, directly impacting cost efficiency and productivity. By ensuring exact specifications, these components significantly reduce material waste during production. When manufacturers utilize precision parts, they achieve a better fit and finish, which minimizes the need for rework or replacements. This streamlined process not only leads to substantial cost savings but also allows resources to be allocated effectively, enhancing overall operational efficiency.

**Tips for Improving Cost Efficiency with Precision Parts:**

1. Invest in high-quality machinery that can produce precision parts consistently, reducing variability and defects.

2. Optimize the design process by utilizing computer-aided design (CAD) software to simulate performance and identify potential waste before physical production.

3. Establish strong relationships with suppliers who specialize in precision manufacturing to ensure access to advanced technologies and materials that enhance product quality.

The integration of precision metal parts ensures that manufacturers can meet market demands while remaining competitive. By focusing on reducing waste and improving productivity through precision engineering, companies can not only lower operational costs but also deliver higher-quality products to their customers, ultimately driving success in modern manufacturing.

The advancements in precision metal parts have been significantly influenced by technological developments across various manufacturing sectors. According to recent market analysis, the sheet metal processing equipment market is projected to witness notable growth, driven by the increasing demand for cutting, forming, and bending processes. The growing adoption of automated and intelligent manufacturing solutions further enhances the precision capabilities of these equipment, enabling industries to meet the rising demands for high-quality metal parts.

Moreover, the laser welding market is expected to expand, reaching approximately USD 4,227.1 million by 2035. This growth can be attributed to the precision and efficiency that laser welding technology brings to various applications, including automotive and aerospace sectors. Additionally, the review of multi-material composite gears indicates a shift towards integrating lightweight materials while maintaining transmission performance. This reflects a broader trend in manufacturing where the combination of advanced materials and precision engineering is essential for achieving optimal performance and competitive advantages in modern industries.

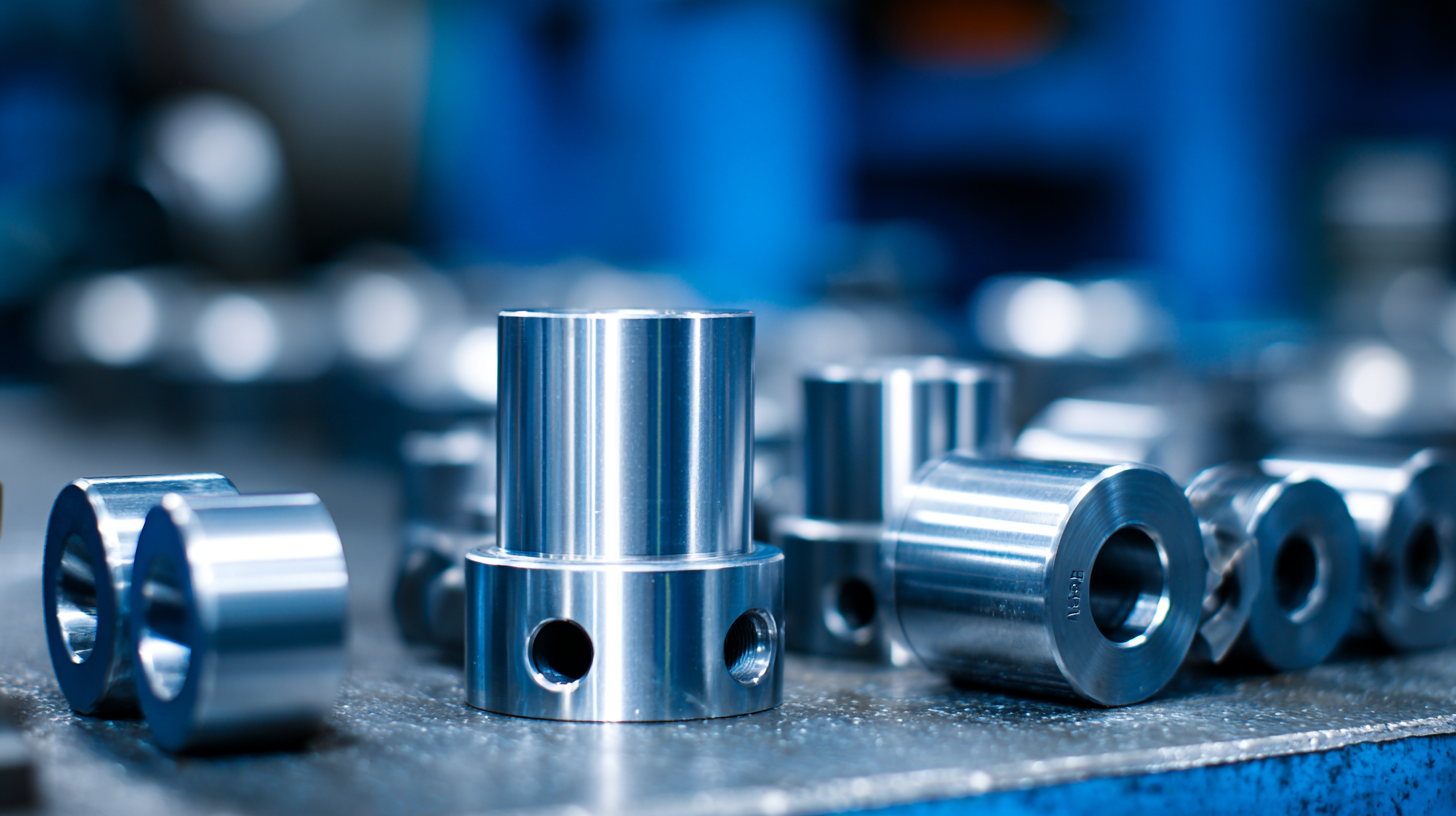

The future of manufacturing is increasingly intertwined with precision metal parts, driven by advancements in technology and the changing needs of various industries. As sectors such as robotics, semiconductor manufacturing, and renewable energy expand, the demand for components like precision ball screws intensifies. These components serve as crucial mechanical elements that convert rotational motion into linear movement, ensuring accuracy and efficiency in high-performance applications. The impact of such precision engineering is evident in the push for greater automation and productivity in modern manufacturing settings.

Simultaneously, the rise of additive manufacturing, particularly in metal 3D printing, highlights a significant trend in this domain. Unlike traditional methods that subtract material, additive manufacturing builds components layer by layer, which opens up new possibilities for design complexity and material efficiency. This innovation not only enhances the precision of metal parts but also allows for customization and rapid prototyping, vital for industries adapting to ever-changing market demands. As manufacturers embrace these technologies, the synergy between precision metal parts and advanced manufacturing processes will likely shape the landscape of production in the coming years.

| Dimension | Material | Utilization (%) | Industry Impact |

|---|---|---|---|

| 2.5 mm | Aluminum | 75% | Aerospace |

| 5 mm | Stainless Steel | 85% | Automotive |

| 3 mm | Copper | 65% | Electronics |

| 4 mm | Titanium | 70% | Medical |

| 1.5 mm | Carbon Steel | 80% | Construction |