In the world of manufacturing, Red Copper Parts play a crucial role. Known for their excellent conductivity and corrosion resistance, these components are utilized in various industries. Dr. Emily Carter, a leading expert in materials science, once stated, "Red Copper Parts bridge the gap between efficiency and reliability."

These components are often used in electrical applications, from circuit boards to wiring. Their unique properties make them ideal for high-performance environments. However, reliance on Red Copper Parts can present challenges. For instance, they can be more expensive than alternatives, which may strain budgets.

Despite their advantages, manufacturers must weigh the cost against the benefits carefully. Investment in Red Copper Parts can pay off in durability and longevity. Yet, it's essential to consider all factors in any project. In a fast-paced industry, making the right choice is critical.

Red copper parts are components made primarily of copper, known for their excellent thermal and electrical conductivity. These parts can be found in various applications, ranging from electrical wiring to plumbing fixtures. The distinct reddish appearance of copper gives these components unique aesthetic qualities as well. Many industries prefer red copper for its durability and resistance to corrosion.

Applications of red copper parts are diverse. In the electronics industry, they are used in circuit boards and connectors. In the plumbing field, they serve as pipes and fittings. However, the production of red copper parts is not without challenges. The process can be energy-intensive and may lead to environmental concerns. Additionally, improper handling can result in issues like oxidation.

Red copper parts offer both advantages and drawbacks. They excel in conductivity but require careful installation to prevent issues. The balance between performance and sustainability must be assessed regularly. Understanding these complexities helps manufacturers and consumers make informed choices about red copper parts.

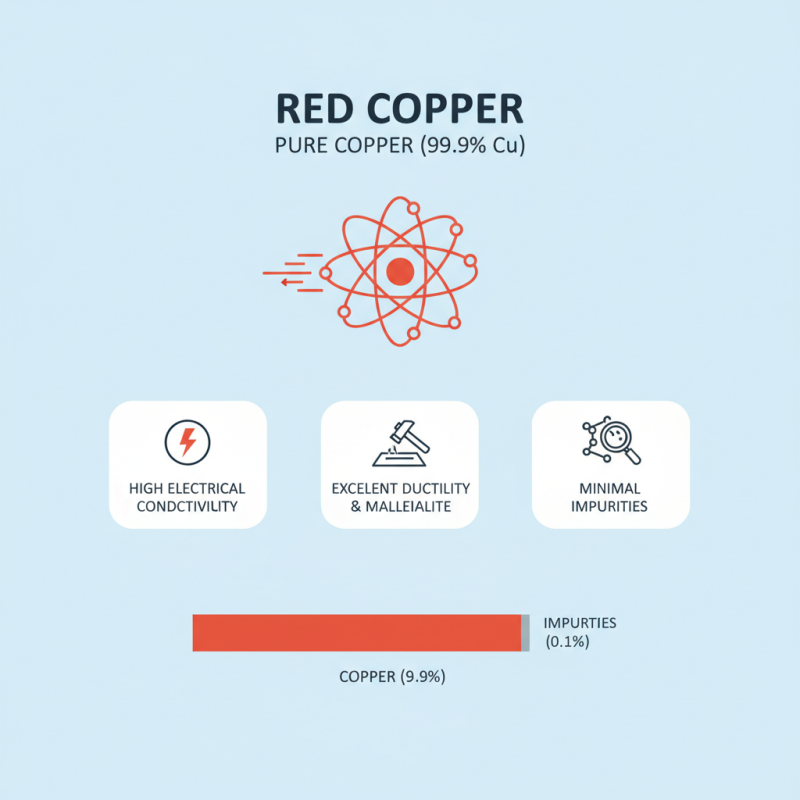

Red copper, often referred to as pure copper, is renowned for its high electrical conductivity. This conductivity is due to its atomic structure, which allows electrons to flow freely. Red copper is composed of nearly 99.9% copper. It contains minimal impurities, giving it unique properties. These include excellent ductility and malleability.

In various applications, red copper plays a crucial role. In electrical components, it is used for wiring and circuit boards. Its ability to withstand heat makes it ideal for cookware. However, one must consider the potential for oxidation. Over time, red copper can tarnish, which may be undesirable in certain situations.

Tips: When using red copper items, cleanliness is vital. Regular cleaning prevents oxidation. For cookware, using a gentle scrub is effective. Avoid harsh chemicals that can damage the material. When crafting with red copper, precise techniques are essential. Mistakes in measurement can lead to waste. Always double-check dimensions before cutting.

Red copper parts play a vital role in various industries. Their unique properties make them ideal for a range of applications. According to a recent industry report, the demand for red copper components is projected to grow by 5% annually through 2026. This growth highlights the increasing reliance on red copper in critical sectors.

One common use of red copper parts is in electrical applications. Red copper's excellent conductivity allows it to perform remarkably well in wiring, connectors, and circuit boards. For instance, electrical connections in high-performance motors utilize red copper to minimize energy loss. Another study showed that copper components enhance efficiency by up to 30% compared to aluminum alternatives. However, these benefits often hinge on proper installation and maintenance, which are sometimes overlooked.

Red copper is also frequently used in plumbing. Its resistance to corrosion makes it suitable for piping and fittings. In high-humidity environments, red copper reduces the risk of leaks. Yet, there's a downside. Over time, red copper can become stained or develop patina, which may lead to additional maintenance challenges. Research indicates that nearly 20% of plumbing installations encounter issues due to neglect. Thus, while red copper parts offer significant advantages, careful attention is necessary for optimal performance.

Red copper parts have gained popularity in various industries due to their unique properties. One significant advantage is their excellent thermal conductivity. According to research, red copper can conduct heat approximately 80% more efficiently than aluminum. This characteristic makes it ideal for applications requiring rapid heat transfer, such as in automotive radiators or heat exchangers.

Another notable benefit of red copper parts is their impressive resistance to corrosion. The Department of Energy reported that copper's natural oxidation creates a protective layer, which prolongs its lifespan in harsh environments. In contrast, alternatives like steel often require additional coatings, raising costs and maintenance needs. While red copper parts can be pricier upfront, the long-term savings in maintenance and replacement can justify the investment.

However, the adoption of red copper parts is not without challenges. Their production can produce more emissions than some alternatives. This aspect raises questions about sustainability. Additionally, some applications may still require the enhanced strength offered by materials like steel, making red copper unsuitable in specific contexts. The balance between efficiency and material properties is a factor that companies must consider carefully.

Red copper parts are valued for their excellent conductivity and durability. However, they require proper maintenance to ensure longevity and performance. Regular cleaning is crucial to prevent oxidation. A simple wipe with a damp cloth can remove surface debris. However, some dirt may need more effort. Using mild soap and warm water is often effective. It’s essential to dry the components promptly to avoid moisture damage.

Additionally, checking for wear and tear is vital. Over time, red copper parts might develop scratches or other imperfections. Close inspection can reveal issues early. If corrosion is present, it can significantly impact functionality. Some reports indicate that untreated copper can lose up to 30% efficiency. Using protective coatings can mitigate this risk. However, these coatings must be reapplied periodically, which requires planning and time.

Environment plays a role too. Humid conditions can accelerate deterioration. If you live in such areas, consider more frequent maintenance. Recognizing these factors is critical. While red copper components are robust, they are not indestructible. Each part has its limits and needs thoughtful care to serve effectively. Balancing everyday use with attentive maintenance is key to maximizing their lifespan.