Choosing the right machined aluminum parts can be challenging. Quality is crucial for performance. Many factors affect your decision. Understanding these factors is essential.

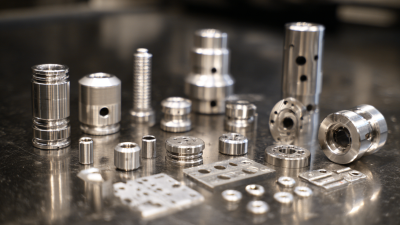

Machined aluminum parts are popular in various industries. They offer strength and lightweight properties. However, not all aluminum parts are created equal. The differences in manufacturing processes can lead to varying results. Some suppliers may cut corners, resulting in parts that do not meet specifications.

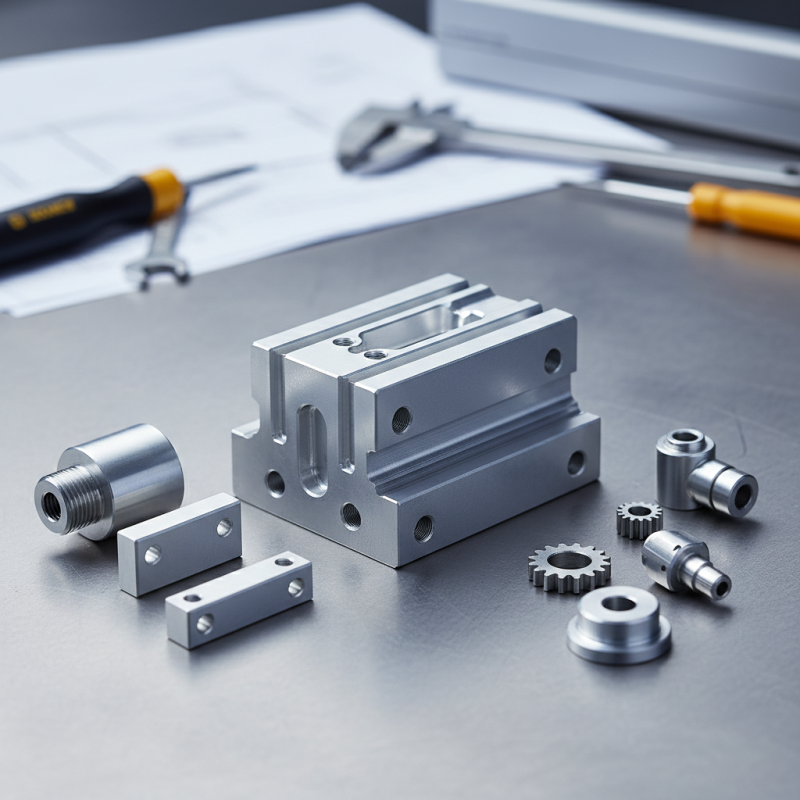

It's important to reflect on your needs. Are you looking for precision or durability? Consider how the part will be used. The perfect choice should balance quality with cost. Make sure to research suppliers thoroughly. Trustworthy manufacturers can make all the difference. In the end, the right machined aluminum parts contribute to your project's success.

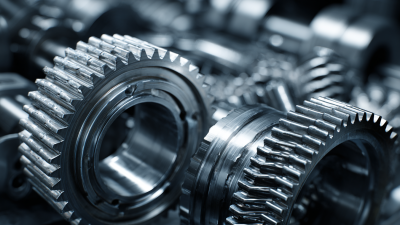

Choosing machined aluminum parts involves understanding their composition and properties. Aluminum is lightweight, strong, and resistant to corrosion. These features make it a popular choice in various industries. When selecting aluminum parts, consider the grade of aluminum used. Different grades can impact strength and durability. For instance, 6061 offers good mechanical properties, while 7075 is stronger but more expensive.

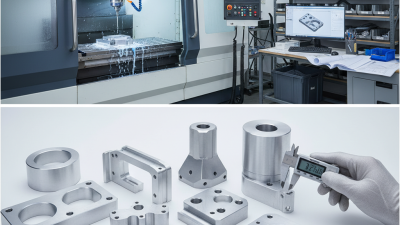

Another essential aspect is the machining process. Precision in machining ensures parts fit correctly and perform as intended. Techniques such as CNC machining allow for high accuracy. However, not every machining method suits every design. Some designs may require more intricate processes, which can increase costs.

Pay attention to the finish of the parts. Anodizing can enhance corrosion resistance but may add time to production. Ultimately, it's crucial to balance quality and budget. Sometimes, a less expensive option may not meet performance requirements. Reflecting on these factors can guide you to make informed choices.

When selecting aluminum materials for machined parts, several key factors come into play. The specific application is crucial. Different industries may require specific grades of aluminum. For instance, aerospace applications often utilize 6061 aluminum due to its excellent mechanical properties. Similarly, automotive parts might favor 5082 for its durability. Knowing the demands of your project will guide your choice.

Another important consideration is the aluminum’s alloy composition. The right alloy can significantly affect performance. Alloying elements like magnesium, manganese, or silicon will alter properties like strength and corrosion resistance. Picking the wrong alloy can lead to unforeseen problems. Always evaluate mechanical properties like tensile strength or fatigue resistance based on your needs.

Surface finish is equally vital. Depending on the environment, a specific finish may be required. Anodizing can enhance corrosion resistance or improve aesthetics. However, achieving the right finish can be challenging and costly. Miscommunication with your provider could lead to disappointment. Therefore, ensure clarity in your specifications and measurements.

When choosing machined aluminum parts, evaluating tolerance and precision is crucial. Tolerance refers to the acceptable limit of variation in a physical dimension. For instance, a report by the American Society of Mechanical Engineers indicates that precision can be critical, with tolerances often specified within ±0.005 inches. This level of precision is vital for applications in aerospace and automotive sectors, where even minor deviations can lead to significant performance issues.

Understanding the application of the parts is essential. Different applications may require tighter tolerances. For example, aerospace components might need tolerances as tight as ±0.001 inches. However, some manufacturers may struggle to achieve these standards consistently. This inconsistency can lead to costly rework or compromised product integrity. It is important to assess the manufacturer's capabilities and past performance records to ensure they can deliver the required precision.

Another factor to consider is the material and machining process. Each process comes with its own challenges. CNC machining provides high precision, but the skill level of the operator can vary significantly. A report from the Precision Metalforming Association highlights that up to 25% of machining errors occur due to operator inexperience. It’s important to question and verify operator training and experience to mitigate the risk of defects in machined components.

When selecting machined aluminum parts, evaluating surface finishes is crucial. The right finish can significantly enhance durability and performance. Anodizing is a popular choice, providing a protective layer against corrosion. However, it may not be suitable for all applications. Some users overlook how certain surfaces can affect adhesion for paints or adhesives.

Brushed or polished finishes offer aesthetic appeal but vary in durability. A polished surface looks sleek but may scratch easily. On the other hand, a brushed finish can hide minor flaws better but may also wear down over time. Think about the operational environment. Outdoor components need stronger protection than those used indoors.

Ignoring surface treatments can lead to costly failures. For instance, untreated aluminum may corrode quickly in harsh conditions. It’s essential to consider not just the initial cost but the long-term implications of your choice. Before finalizing a selection, ask critical questions. Will the part withstand environmental stress? Is the surface finish appropriate for its intended use?

| Finish Type | Application | Durability Rating | Cost | Additional Treatments |

|---|---|---|---|---|

| Anodizing | Aerospace, Automotive | High | $$$ | Dyeing, Sealing |

| Powder Coating | Furniture, Outdoor | Medium | $$ | UV Resistant |

| Brushed Finish | Consumer Electronics | Low | $ | Clear Coating |

| Chemical Film | Military, Marine | Very High | $$$ | Corrosion Resistance |

| Electropolishing | Food, Medical | High | $$$ | Biofilm Prevention |

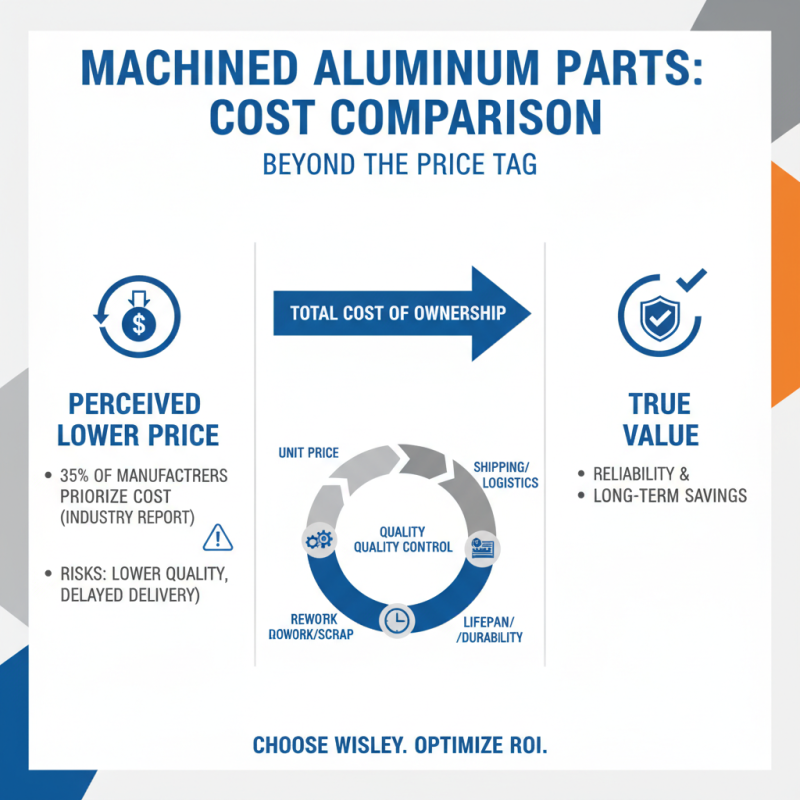

When comparing costs for machined aluminum parts, several factors come into play. According to a recent industry report, nearly 35% of manufacturers cite cost as a decisive factor when choosing suppliers. Yet, perceived lower prices often come with strings attached. Lower-cost suppliers may compromise on quality or delivery timelines, which can impact your project. Thus, understanding the total cost of ownership is crucial.

Quality assessment varies widely among suppliers. Some manufacturers offer certifications and end-to-end process transparency. A significant 40% of companies reported issues with parts from suppliers lacking clear quality protocols. This reinforces the need to prioritize quality, even if it means spending a little more upfront. It’s not just about saving money; it's about investing in reliability and performance.

Engaging with multiple suppliers can unveil hidden costs. Shipping fees, lead times, and overlooked material costs often inflate final expenses. A survey indicated that over 50% of companies experienced unexpected costs in their projects. Therefore, an exhaustive comparison of supplier options is essential. This diligence can prevent budget overruns and project delays. Balancing cost and quality is not just critical; it’s an art that requires careful consideration and sometimes constructive disappointment along the journey.