In the world of precision manufacturing, CNC Machining Centers play a pivotal role. According to a 2022 report by the International Society of Automation, CNC machining is expected to grow by 6% annually over the next five years. This growth reflects the increasing demand for accurate and efficient manufacturing processes. As industry expert John Smith states, “Investing in modern CNC Machining Centers can significantly enhance productivity and precision.”

Today, choosing the right CNC Machining Center is crucial for manufacturers. There are various models available, each optimized for specific needs. Companies must consider factors such as speed, precision, and reliability. While many businesses gravitate towards the latest technology, some may overlook the importance of training staff adequately. Insufficient training can lead to underutilization of these advanced machines.

The landscape of CNC Machining Centers is vibrant yet complex. Companies face challenges in selecting equipment that meets both immediate and long-term goals. New technologies emerge rapidly, creating opportunities but also heightened competition. Manufacturers must continually adapt to thrive in this dynamic environment. The right CNC Machining Center might not only streamline operations but also ensure sustainable growth.

CNC machining centers play a crucial role in precision manufacturing. They combine computer programming with machining to produce parts with high accuracy. According to a recent industry report, precision manufacturing needs tools that can operate within tolerances of less than 0.01 mm. This level of accuracy is vital for industries like aerospace and medical device production.

In 2022, the global CNC machine market was valued at approximately $72 billion. This number is expected to grow due to advancements in technology. Features such as multi-axis capabilities and automated tool changes enhance productivity significantly. However, not all CNC machines deliver the same level of performance. The right choice depends on the specific needs of the manufacturer. Some machines may lack necessary features for complex designs, showcasing a gap in the market.

Moreover, data suggests that many manufacturers struggle with optimizing their CNC processes. Some report inefficient use of materials or machine downtime. This indicates that while CNC technology is advanced, it is not without imperfections. Continuous learning and adaptation remain essential for manufacturers aiming for precision. The journey toward heightened accuracy is ongoing and requires constant evaluation of equipment and processes.

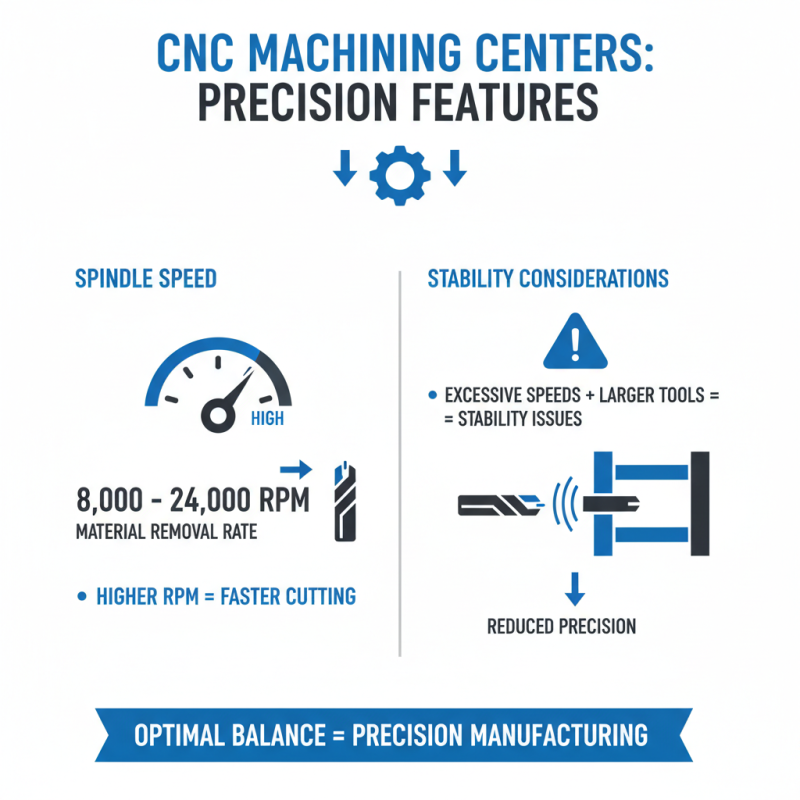

When selecting CNC machining centers, several key features are crucial for precision manufacturing. The spindle speed typically ranges from 8,000 to 24,000 RPM, affecting the material removal rate. A higher RPM allows for faster cutting. However, stability issues may arise with excessive speeds, especially with larger tools.

Another important aspect is the machine's rigidity. A rigid structure minimizes vibrations during operations. This ensures better surface finishes and extends tool life. Industry reports indicate that machines with enhanced rigidity can increase productivity by up to 30%. Pay attention to the construction materials used in the machine.

Tips: Check the axis travel range. A broad range provides greater flexibility in part design. Also, consider the integration of automation features. Many machines now come equipped with robotic loaders that significantly reduce downtime. Balancing automation with human oversight is vital. The right blend can lead to improved efficiency but requires thoughtful implementation.

Accuracy and repeatability are also essential metrics. CNC centers should maintain tolerances within 0.002 inches for high-precision tasks. Yet, many machines struggle to uphold this under continuous use. Regular calibration may be necessary. Balancing cost and performance remains a common challenge in the industry.

In 2023, CNC machining centers are pivotal in precision manufacturing. According to industry reports, the global CNC machining market is expected to reach $100 billion by 2028. This growth is driven by the demand for accuracy and efficiency in production processes.

Investing in advanced CNC machining centers can significantly reduce waste and enhance quality. Many centers now feature automation capabilities. With automated tools, production rates can increase by up to 30%. Precision is crucial in industries like aerospace and automotive, where tolerances can be as tight as 0.005 inches. However, some machines may struggle with complex geometries, requiring skilled operators to troubleshoot.

User feedback highlights both strengths and weaknesses. While accuracy has improved, some users report a steep learning curve. Maintenance can also be a challenge, with certain parts wearing out faster than anticipated. The balance between automation and skilled labor remains an ongoing conversation in the industry. Real-world applications show that while technology evolves, the need for human oversight is still vital for overcoming obstacles.

CNC machining centers are vital for precision manufacturing. Many companies look for the best options available. Performance and cost are key factors in choosing the right center. A recent report notes that accuracy can vary significantly among machines. For instance, some centers achieve a tolerance of ±0.01 mm, while others struggle to reach ±0.1 mm.

Cost-effectiveness is another concern. The initial investment for a high-performance center can start at $100,000. However, lower-cost options may result in higher operational costs. Maintenance and tooling can add up quickly. A study revealed that machines used in high-volume production can save 20% on unit costs due to efficiency. Yet, if they often require repairs, those savings can vanish.

Many manufacturers overlook the importance of understanding their specific needs. Not every center suits every project. For low-volume jobs, ultra-high precision may be unnecessary. Balancing the performance and costs involves careful consideration. It's crucial to analyze each machine's capabilities against potential project requirements.

This chart compares the performance and cost of the top 5 CNC machining centers. Each center is evaluated based on precision (measured in microns), speed (measured in RPM), and cost (measured in thousands of dollars). The data reflects the capabilities of modern CNC machines critical for precision manufacturing.

CNC machining centers are crucial in many industries. They ensure precision in production, which is essential for high-quality outcomes. These machines excel in creating complex parts with intricate designs. The automotive industry heavily relies on CNC machining for engine components and transmission parts. Accuracy in these parts is non-negotiable.