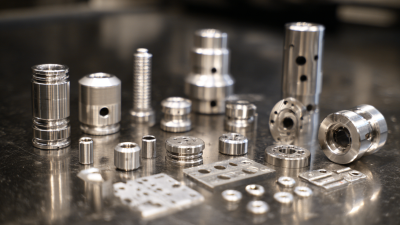

In the realm of modern manufacturing, selecting the right components is critical to the success of any project. Among the various materials available, aluminum has emerged as a favored choice due to its lightweight, durability, and excellent machinability. Consequently, aluminum CNC machining parts have gained significant attention for their precision and versatility in a wide array of applications. However, with numerous options available on the market, choosing the best aluminum CNC machining parts for your specific project can be a daunting task.

To make an informed decision, it is essential to consider several factors that influence the performance and suitability of aluminum CNC machining parts. These include the specific requirements of your project, such as dimensional tolerances, surface finishes, and the intended use of the components. Understanding these parameters will help narrow down your options and ensure that the selected parts meet the necessary standards for quality and functionality. In this guide, we will explore the key considerations and best practices for selecting aluminum CNC machining parts, equipping you with the knowledge to enhance your manufacturing process and achieve outstanding results.

Aluminum CNC machining is a vital manufacturing process in various industries, known for its precision and efficiency. The basics of this process involve using computerized tools to cut and shape aluminum into desired parts, providing both high tolerance levels and excellent surface finish. According to a report by the market research firm, Grand View Research, the global CNC machine market is expected to reach $100 billion by 2025, highlighting the growing demand for high-quality machined components, particularly in the aerospace, automotive, and electronics sectors.

Understanding the intricacies of aluminum as a machining material is crucial for ensuring the best results in any project. Aluminum is favored for its lightweight, high strength-to-weight ratio, and corrosion resistance. The properties of aluminum, often characterized by a density of 2.7 g/cm³ and a tensile strength ranging from 70 to 700 MPa, make it a versatile choice for custom parts. Additionally, CNC machining can produce complex geometries that are integral to innovative design, which is essential for industries requiring precision and reliability. An analysis by Techspex indicates that aluminum machining can offer a reduction in production costs by up to 30%, making it not only effective but also economically viable for manufacturers.

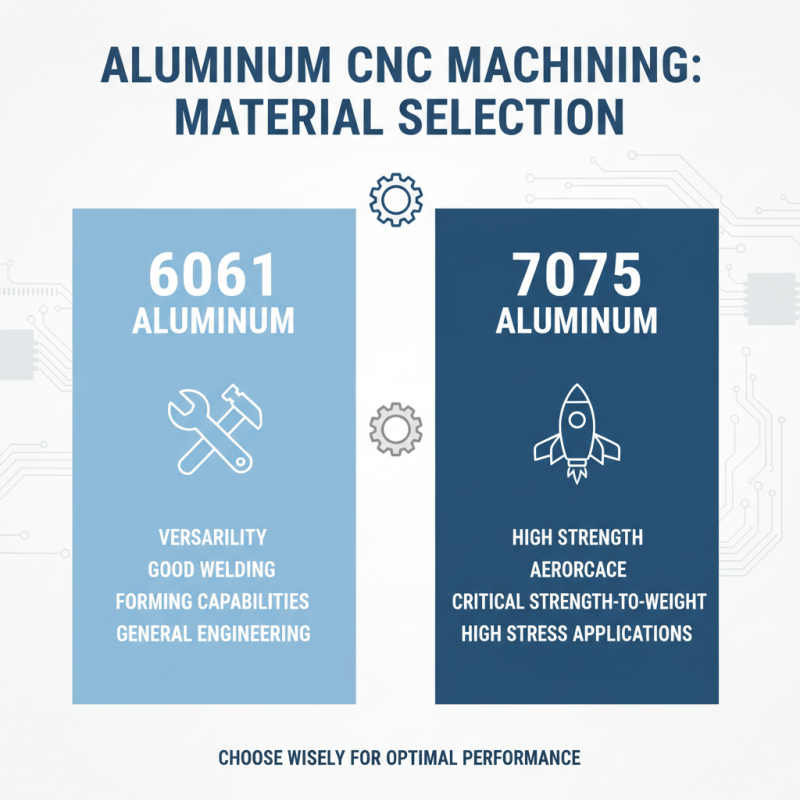

When selecting the best aluminum CNC machining parts for your project, several key factors must be considered to ensure optimal performance and efficiency. First and foremost is the material grade of aluminum. According to a report by the Aluminum Association, different grades, such as 6061 and 7075, offer varying strengths, corrosion resistance, and machinability. For example, 6061 aluminum is often favored for its versatility and is ideal for welding and forming, while 7075, being stronger, is preferred in aerospace applications where strength-to-weight ratio is critical.

Another critical factor is the tolerances that the project demands. The precision of CNC machining allows for very tight tolerances, often within 0.005 inches. Industry statistics indicate that up to 80% of machining failures can be attributed to improper tolerances. Therefore, clearly defining the required tolerances at the outset can prevent costly errors and delays. Additionally, the complexity of the part design should align with the capabilities of the CNC machining equipment. A study published in the Journal of Manufacturing Processes highlights that understanding the limitations and strengths of machining technology can significantly affect design feasibility and production timelines. Preparing for these aspects will ultimately lead to more successful project outcomes in CNC machining.

When selecting aluminum CNC machining parts for your project, evaluating tolerance and finish options is crucial to achieving the desired performance and aesthetics of the components. Tolerance, which refers to the allowable variation in dimensions, plays a significant role in determining how well the parts will fit together and function in their intended application. Depending on the specific requirements of your project, you may need to opt for tighter tolerances, which can enhance the precision of the assembly but may also increase manufacturing costs. Understanding the level of precision needed for your components is essential, as it directly impacts the overall quality and functionality of the finished product.

In addition to tolerance, the surface finish of aluminum parts can significantly influence both their appearance and performance. Common finish options range from anodizing and plating to polishing and bead blasting, each offering different benefits. For example, anodizing not only improves corrosion resistance but also adds an attractive aesthetic to the surface. Conversely, a smoother finish like polishing can reduce friction and wear in moving parts, enhancing their longevity. It's important to consider how the chosen finish will affect the part's functionality, especially in applications where environmental exposure or wear and tear are concerns. By carefully evaluating both tolerance and finish options, you can ensure that your aluminum components meet the precise demands of your project while achieving the desired look and feel.

This chart represents the tolerance levels for various aluminum CNC machining parts. Tolerance is a critical factor in manufacturing, as it ensures the parts fit and function correctly in their intended applications.

When it comes to selecting aluminum alloys for CNC machining applications, the choice of material plays a pivotal role in the overall success and functionality of your project. Different aluminum alloys offer varying properties such as strength, corrosion resistance, and machinability, which are essential factors to consider based on the requirements of your application. For instance, 6061 aluminum is widely used for its good mechanical properties and weldability, making it suitable for a range of structural parts. On the other hand, 7075 aluminum, known for its high strength and resistance to stress, is favored in aerospace applications.

Tips: When selecting an aluminum alloy, assess the mechanical properties required for your project, including tensile strength and hardness. Additionally, consider environmental factors such as exposure to moisture or chemicals, as these can influence the choice of alloy.

Furthermore, it is crucial to evaluate the machinability of the aluminum alloy. Alloys like 5083 are easier to machine and allow for smoother edges, making them ideal for intricate designs. In contrast, some high-strength alloys may require specific tooling or machining strategies to achieve desired surface finishes.

Tips: Always consult with a materials specialist or conductor before making a decision, as they can provide insights into the optimal alloy choice based on your machining capabilities and end-use requirements. By understanding the distinctions between different aluminum alloys, you can ensure that your CNC machined parts meet both performance standards and project deadlines.

| Aluminum Alloy | Common Uses | Strength (MPa) | Weight (g/m2) | Corrosion Resistance |

|---|---|---|---|---|

| 6061 | Structural components, automotive parts | 250 | 2700 | Moderate |

| 7075 | Aerospace, high-stress parts | 570 | 2800 | Low |

| 5052 | Marine applications, fuel tanks | 210 | 2700 | Excellent |

| 2024 | Aircraft structures, military vehicles | 580 | 2700 | Moderate |

| 3003 | Cookware, chemical equipment | 130 | 2700 | Good |

When considering aluminum CNC machining parts for your project, budgeting and cost considerations are essential to ensure that you make the right choice for your needs. The manufacturing process itself can variably impact the cost, depending on factors such as complexity, quantity, and finish. Understanding these variables will help you create a realistic budget that accommodates both the initial costs and any potential additional expenses.

One key tip for managing costs effectively is to evaluate the design of your parts carefully. Simplifying design requirements can lead to significant cost savings. For instance, reducing intricate features and opting for standard sizes can minimize machining time and reduce material waste. Additionally, sourcing material directly can often provide better pricing than purchasing pre-fabricated parts.

Another important consideration is the expected quantity of parts. Many machining services offer bulk pricing discounts, so increasing your order size could lead to substantial savings per unit. It's also wise to request quotes from multiple manufacturers to compare pricing and services offered. This way, you can ensure that your selected option meets both your budget constraints and project specifications without compromising on quality.