In the competitive field of medical devices, selecting the right Medical Device Piston Assembly is crucial. Dr. Emily Carter, a leading expert in biomedical engineering, emphasizes this: "Choosing the right piston assembly can make or break a device’s performance." This highlights the importance of careful evaluation.

When considering a Medical Device Piston Assembly, various factors come into play. Materials, sizes, and compatibility with other components are vital. Decisions in these areas can significantly impact the efficiency and reliability of medical devices. For instance, the wrong material choice might lead to device failure.

Yet, many companies rush this process. They may not weigh all the options thoroughly. This oversight can result in costly redesigns or even product recalls. Ensuring a comprehensive selection process is essential for avoiding pitfalls in the future.

Medical device piston assemblies play a crucial role in several healthcare applications. They are responsible for creating pressure in syringes, infusion pumps, and various other devices. The efficiency of these assemblies directly impacts the functionality of the medical equipment. Understanding their design and operation is key for selecting the right piston assembly for your needs.

One critical aspect to consider is the materials used in the assembly. Different materials affect durability and compatibility with various medications. Additionally, the shape and size of the piston are essential. They must fit precisely within the device to prevent leakage or malfunction. Always request technical specifications to ensure the assembly meets your standards.

**Tips:** When evaluating piston assemblies, consider testing samples before a bulk purchase. This practice can uncover potential issues early. Pay attention to user feedback from medical personnel. It often reveals flaws that specifications might not convey. Furthermore, ensure you are aware of the assembly’s maintenance needs. Ignoring upkeep can lead to performance decline over time.

This bar chart compares the performance ratings of various medical device piston assemblies, illustrating how each assembly performs in terms of efficiency and functionality.

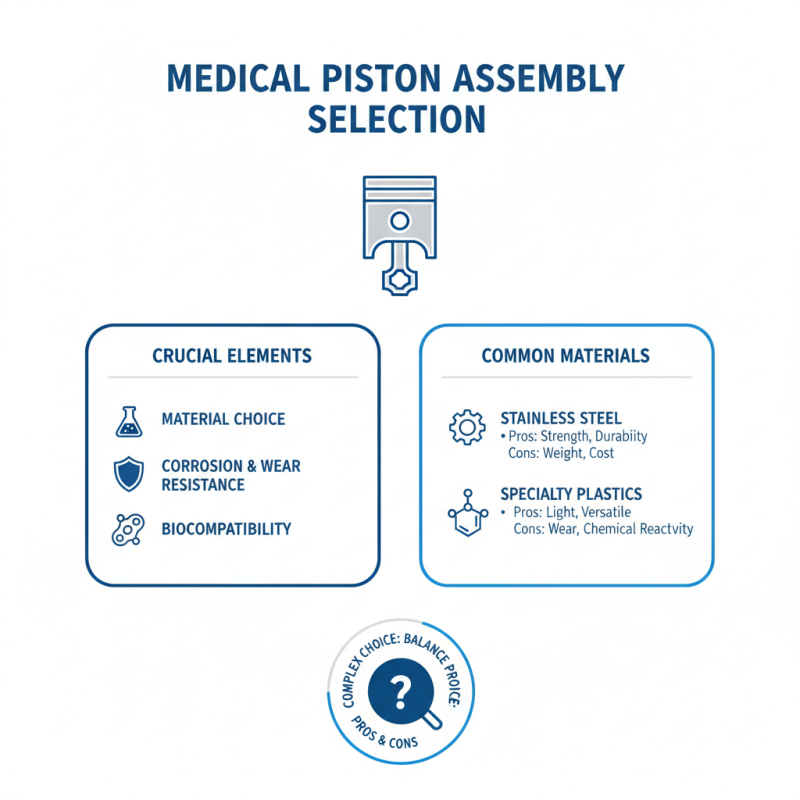

When selecting a piston assembly for medical devices, several crucial elements come into play. Material choice is vital. Medical piston assemblies often need to resist corrosion and wear while maintaining biocompatibility. Common materials include stainless steel and certain plastics. Each material has benefits and drawbacks. Sometimes, the best option might not be so clear.

The assembly's design also matters significantly. A well-designed piston assembly will facilitate smooth operation. It should provide accurate dosage and reduce the risk of contamination. Precision in manufacturing tolerances is essential. Imperfections can lead to malfunction or inaccurate results. Always check the specifications and ensure that they align with the device's requirements.

Testing and validation play a key role. Before finalizing your choice, conduct tests in relevant conditions. This can highlight potential issues that may not be apparent during initial reviews. Evaluating feedback from users can also offer insights into performance and reliability. Remember, a thoughtful assessment can lead to more effective medical device solutions.

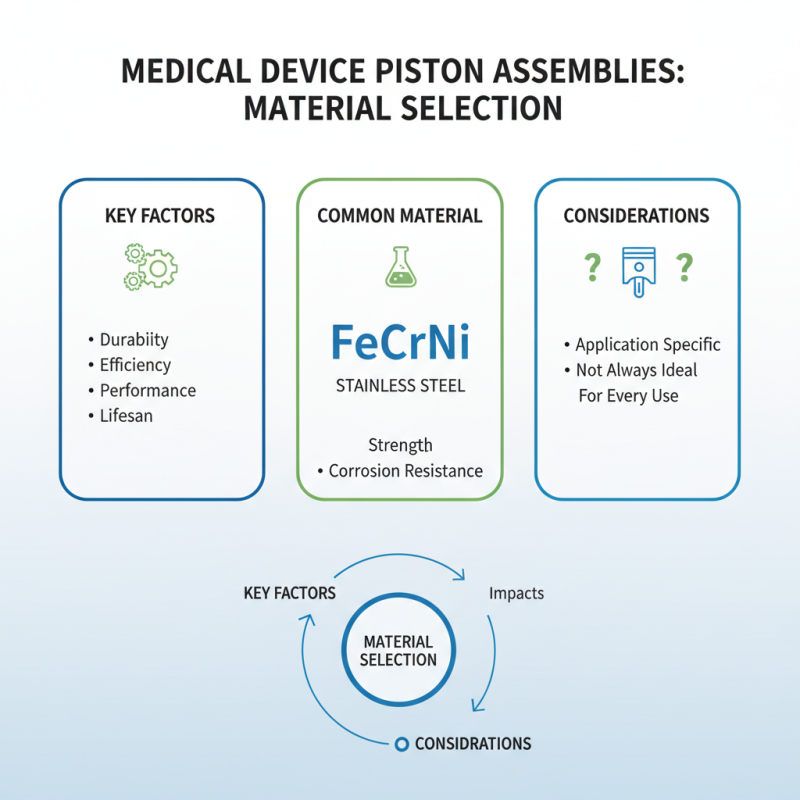

When it comes to medical device piston assemblies, material selection is crucial. Choosing the right components ensures durability and efficiency. The materials used directly impact performance and lifespan. Stainless steel is often a go-to for its strength and resistance to corrosion. However, it may not always be the most suitable for every application.

Silicone or rubber components can offer flexibility and resistance in certain conditions. It's important to consider the specific environment in which the device will be used. Factors like temperature variations, exposure to chemicals, and mechanical stress must be assessed. Sometimes, wrong materials lead to device failure or unexpected wear.

**Tip:** Always test materials under conditions they will face. It's vital to verify compatibility with other components in the assembly. Balancing quality and cost can be tricky. Some cheaper options might save money upfront but could lead to higher costs in the long run.

**Tip:** Seek expert opinions when in doubt. The right choice isn’t always obvious. Analyze past case studies for insights. Reflect on which materials stood the test of time. That could steer you toward a more durable solution.

Choosing the right piston assembly for medical devices requires careful consideration of compatibility with specific standards. The assembly must meet stringent requirements. This often includes ISO certifications and compliance with FDA regulations. A mismatch could lead to device malfunctions.

Compatibility should extend to materials used in the piston. Some materials may cause contamination or may not withstand sterilization processes. Testing these materials can be an overlooked aspect. The impact on patient safety is critical. Additionally, interfacing with other components is vital. Each part must work seamlessly without friction or leaks.

Evaluating the piston’s dimensions is another crucial step. A slight variation can affect the performance of the entire device. It’s essential to involve engineers early in the design phase. They can identify potential issues that may arise later. Adapting to changing regulations can also pose challenges. Frequent updates to standards require regular reviews and adjustments. This complexity can be daunting but is necessary for ensuring patient safety.

When choosing a medical device piston assembly, evaluating the manufacturer's reputation is crucial. A well-regarded manufacturer often signals reliability. Check customer reviews and testimonials. Are they satisfied with the product's quality? Pay attention to their experiences, both positive and negative. This can reveal a lot about manufacturing standards.

Support services are equally important. After purchasing, you may encounter issues. How responsive is the manufacturer to inquiries? A supportive manufacturer offers guidance through installation and troubleshooting. Prompt customer service is essential for minimizing downtime. Look for warranties or guarantees. These indicate the manufacturer stands behind their product.

Consider industry certifications as well. They often highlight a commitment to quality and safety. However, not all manufacturers have certifications. This could raise red flags. Take time to research thoroughly. It may feel tedious, but this is vital for your selection process. Manufacturers should also be transparent about their processes. Transparency builds trust. It is okay to seek clarification on unclear details. A thoughtful approach will lead to better decisions.

| Criteria | Rating (1-10) | Comments |

|---|---|---|

| Manufacturer Reputation | 9 | Strong track record in the industry. |

| Product Quality | 8 | High standards, minimal defects reported. |

| Technical Support | 7 | Responsive but limited service hours. |

| Customer Service | 8 | Courteous and helpful representatives. |

| Warranty and Support Services | 9 | Comprehensive warranty policy. |

| Price vs Quality | 8 | Fair pricing for quality offered. |